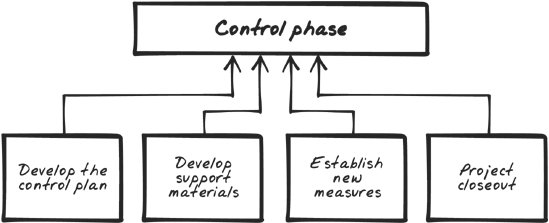

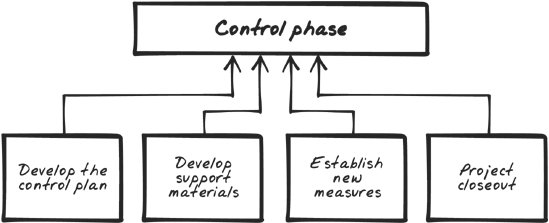

7.8. Control The "C" in DMAIC is for control, and this step, like the others, can be thought of in a heavy way or in a light way, depending on the industry you're in and the focus of your project. The basic intention of control is to make sure the organization commits to institutionalizing the revised process and ensuring its enhanced performance. From this viewpoint, every process program needs a "C" step. As discussed in Part 1 of this book, corporate habits, routines, and cultures can be hard things to change. When you introduce a new process or adjust an existing one, the company may have a tendency to want to revert back to their old ways. That's understandable. The old ways are usually very familiar, so they are easy to use. They seem natural because "that's the way things have always been done." And, good or bad, they were at least predictable. They were known quantities. But honoring such entropy-driven momentum is not a formula for improvement. And it's certainly not a formula for success. The action behind control is to support the new way with the kinds of resources needed to make the new way the accepted way. To do this, you want to prevent the organization from reverting back to the old way. You want to set controls into the environment to keep the process on a true course. A common disappointment in the field of process improvement is lack of control. We have heard stories of organizations that spend money and time to develop a program, and what they produce may end up being very good. But the program fails to take hold. The organization at large doesn't embrace it. It dissipates over time. Evaporates. The reason usually boils down to the issue of Control. The organization failed to set the right structures in place to control the use of the new program. This, of course, takes planning, and resources, and investment from management. This is the light view of control. The heavy view is much more rigid and formal. It typically applies to manufacturing environments, where processes are embedded in substantial machinery and robotics. Control here is more than a concept of preparedness. It's the monitoring and maintenance of precise specifications, it's the accurate control of parts inventories, it's rigid adherence to maintenance schedules. But for the purposes of this book, we won't go into the deep end of control. Since we are focused mainly on the use of Six Sigma in technology development environments, we'll keep control constrained to its management meanings. This involves such tasks as the developing a Control Plan, allocating resources, and formally transitioning the processes into the production environment. Figure 7-11 illustrates the control phase of DMAIC. Figure 7-11. In the control phase of DMAIC, the objective is to deploy improved processes into the organization. This involves documenting what the improvements are, how they affect the system as a whole, what training will be provided to process owners, and what support materials are available to operate and maintain the refined processes.

7.8.1. The Control Plan You can think of the Control Plan in the same way you think of a deployment plan or an implementation plan in the realm of systems or software development. The Control Plan is a plan you create to coordinate the smooth deployment of the new or refined processes out into the organization. Basically the Control Plan describes what is being introduced, how it is to be used, and what materials exist to support it. Following is an abbreviated list of some of the sections you might want to include in a Control Plan:

Description of the process additions or revisions This section describes what is being introduced into the organization. If it is a new process element, the description will include the purpose of the element, the steps involved or embedded in the process, the primary and secondary actors involved, inputs and entry criteria, and outputs and exit criteria. If the element is a revision of an existing process or procedure, then the descriptions are revisions of the existing documentation.

Mapping of the new functionality into existing process streams and flows Six Sigma is all about process improvement. But process improvement is not an isolated event. Most of the time, a process is part of a family of processes that represents a system. Systems are interrelated and interdependent entities. One process usually affects another. And so if you alter one process, you should have an understanding of how that change might impact upstream or downstream activities. A good way to do this is with a process map, or with revisions to existing process maps. These may be visual depictions or narrative descriptions. These maps will orient users to the new flows that are being incorporated into the system.

Identification of process owners Process owners usually include three categories of people: The primary actors who are responsible for ensuring that the process is executed properly The secondary actors who are needed to provide input into the process or will use the output resulting from the process Management that relies on the process to account for standard or regulatory activity

It's a good idea to specifically identify these owners in the Control Plan. This helps establish the required readership for the Control Plan.

Description of production changes When a process is modified or a new process is introduced, chances are the change will have a material impact on production. The product will change in some way. The change may be in the inputs that are fed into the process. It may be in the form that the outputs from the process take. The change may be in cycle time. A description of this change is useful in the Control Plan. If your people are going to be seeing something new appear in the production process, then they need to be prepped for what that new thing is. Since unexpected newness is typically called a deviation and counted as a defect, your plan should describe what the new processes will be producing.

Location and access of support materials The new processes you have put into place should be accompanied by some form of supporting materials. These might be flowcharts, procedure manuals, reference sheets, forms, and other similar kinds of process tools. In the Control Plan you should identify what these assets are and where the users can find them. (See the following "Control Tools section.) The location of the materials should describe any access requirements, any check-out procedures, and the rules and standards regarding material versioning. The idea here is to guide the audience to the right materials: the latest and most complete versions. This way, they are ensured to use the most accurate release editions of the materials.

Training schedule The concept of training should always go hand in hand with introducing new process components into any system. Many times this is a forgotten or neglected consideration. But the issue of training is essential to the successful use of any single process or process program. The deployment of the program is best preceded by some regimen of training. This might be coaching-based instruction, classroom training, computer learning, or video training. But whatever form it takes, the delivery of the training should be coordinated with those who will be required to use and manage the process. And so here it is helpful to define the training schedule and the audience that will be required to attend the training. To facilitate this, the organization should expend some energy designing, developing, and packaging the training materials and their manner of presentation.

Deployment schedule The training schedule mentioned above establishes the timeline and focus of training efforts related to the process improvements. The deployment schedule serves a similar purpose. Naturally, an organization will not sneak in a process improvement in the dark, fly it in under radar. It should be a visible activity, a lights-on activity. After all, a single process improvement has the potential to touch and influence many parts of a working system. And so the deployment of the improvements should be part of what's communicated in the Control Plan. The deployment schedule usually identifies when the changeover will occur (and this may necessitate some downtime), who will be involved in the changeover, what systems or segments will be impacted (and what the impact will be), and how long the migration is expected to take.

Process performance measures A final consideration for inclusion in the Control Plan is the performance measures that have been identified for this process. If the measures have not changed, it might be a good idea to still identify them and then reiterate their current applicability. If the process is new or significantly changed, then you may have identified new measures. Here you should consider describing what these measures are, how they are to be collected, what analyses are put against them, and how the analyses are interpreted and reported. The Control Plan can be used to its best potential as a tool to institutionalize the improvements through the formal modification of systems and structures as articulated in the plan. It is a plan that establishes a path of carrying well-designed improvement into production in a permanent and productive way. 7.8.2. Control Tools In one section of the preceding Control Plan, I described the process support materials available for the deployment and regular use of the improvements. These materials can be seen as a series of control tools. These are the process assets, such as development documentation and implementation support material, for ongoing use and management of the process. 7.8.2.1. Policies Policies are typically used to shape executive-level expectations for process use and to demonstrate executive commitment to process adoption. For the new improvements, consider creating appropriate policiesendorsed by managementthat set forth what the organization requires around process use. Policies of this kind are typically short documents (maybe a page or two), and they approach process use from a high level. But they carry the weight of executive mandate, and so they are valuable tools in emphasizing the importance of honoring the organizational way. 7.8.2.2. Standards and procedures This is what is usually considered as the "real" process documentation. These tools are the documented procedure manuals, process steps, and activity standards that guide people in very direct ways in the use of the improvements. The common form of thesecollected togetheris the Instruction Manual. A new automobilea complex system of interrelated processescomes with its Owner's Guide. A new medicationa catalyst of complex organic processescomes with its own Indications and Contraindications Insert. A new human being comes with the 64th edition of Dr. Spock's Baby Guide. These standards and procedures are indispensable components in rolling out new processes or new improvements successfully. 7.8.2.3. Templates and forms The standards and procedures just described are often best supported by what are commonly called reference implementations. That's a fancy expression for "examples." To augment your standards and procedures, the organization might consider developing such process aids as templates, forms, checklists, and best-case examples. These are tools that the practitioners can use to immediately begin using and managing the process. The better designed ones will actually guide the user to effectively use the process. 7.8.2.4. Monitoring and control system protocols Six Sigma retains a deep focus on control throughout its range of activities. This does not let up on deployment. In fact, it takes on a fresh perspective. An organization can use statistical and quantitative techniques to investigate opportunities for process improvement. IT can use the same to determine the most efficient way to improve existing process elements. Likewise, it canand shouldestablish ongoing monitoring and control techniques that will help the organization continually collect performance data that can be amassed as a aid to making improvement decisions in the future. 7.8.2.5. Performance validations This part of the Control Plan describes process improvement characteristics very particular to Six Sigma. These are the performance attributes that can be used to validate the improvements over time, proving that they were worth deploying after all. This is usually a section that describes new or extended forms of effectivity measurements. These may include such metrics as cost benefits, cost savings, throughput increases, defect reduction, profit growth, risk avoidance, fee avoidance. The kinds of metrics you elect to define here will naturally depend on the processes and the improvements you've set into place. 7.8.3. Project Closeout The final activity conducted under control is project closeout. Here you are ready to wrap up the project, perform some last cleanup tasks, and then release the resources to new work. You can structure your closeout activities in the way that best suits your organizational needs. But there are five general activities you might consider. These are typically found as part of the closeout tasks on a typical Six Sigma project: Finalize the documentation. Throughout the project, you and your team have been amassing documentation to drive your decisions and creating documentation to support deployment of your improvements. At this point, you should take a careful inventory of all this material and ensure that it is either ready to be archived for future reference or that it is in a form ready to be published to the relevant groups within the organization. Conduct lessons learned. This is a communal "what did we do right, what did we do wrong" session. This a review session in which the Six Sigma team convenes to identify and discuss the strengths of the current project, and (perhaps more important) to identify and discuss what they did not do so well, and what they might do better the next time around. Communicate the change to the business at large. This communiqué shares the success story with the whole organization. It endorses the concept of continuous improvement and at the same time serves as further evidence that management and the company are committed to the ongoing activity of always making themselves better. Celebrate. Step back and take a look at what you've accomplished. Chances are, what you've accomplished is going to move the company forward, forward in tangible ways. Ways that demonstrably position it closer to its goals. Ways that translates into discrete and measurable factors of business success.

Quick Take CONTROL The control phase is used to roll out process improvements into the organization at large. Since the effect here is to change the existing systems, the rollout needs to be conducted in a coordinated manner. This involves establishing a Control Plan and setting into place control tools:

Control Plan The Control Plan is, in essence, a deployment and implementation plan. It describes what is being changed, who will be impacted, when the change will happen, and what materials are in place to support the new elements. This can include: Definitions of new features Identification of process owners Descriptions of production changes

Control tools In order to control the proper operation of the new processes, it's important to provide the organization with adequate control tools. These are the assets that the process owners can use to integrate the new functionality into existing systems. This material typically includes elements like: Policies Procedures New measures

Project closeout The final formal step in control is project closeout. Even though control is an ongoing process, this step signals the official end of the Six Sigma project. |

|