8.2 Sun Microsystems, Inc.

|

| < Day Day Up > |

|

Sun Microsystems, Inc., sells network servers, data storage systems, engineering workstations, and information appliances for use in a wide range of markets, including telecommunications, financial services, government, manufacturing, education, retail, life sciences, media and entertainment, and health care. Their product line stretches from ultrathin, rack-mountable servers priced under $1,000 to massive, high-integrity systems in configurations costing $10 million or more.

Sun recognizes that business today is all about services—within the enterprise and between enterprises, with and without wires. The Sun-Open Net EnvironmentTM (Sun ONE) TM provides the software products— from developer tools to an industrial-strength operating environment—needed to create, assemble, deploy, and manage services on demand. The Sun ONETM software stack includes identity management, security, integration, Web, application, portal, and messaging solutions.

Sun’s rapidly growing service organization helps customers architect and support their network computing environments. The focus of consulting, education, and support services is on maximizing uptime, increasing productivity, and controlling costs.

Sun’s primary markets are the Global 2000 companies. Specific product growth subsegments include servers, storage, services, and software infrastructure products. Within the Global 2000, Sun targets specific environments and user types. At the highest level, their target environments are enterprise data centers and service provider data centers/telecommunications. In terms of user types, they focus on CXOs, [1] developers, information technology managers, and global sales partners. In terms of priority, the target vertical industries include government, education, financial services, telecommunications, automotive, healthcare, media/entertainment, eManufacturing, retail, life sciences, and transportation. Key customer applications such as ERP, data warehousing, server consolidation, and customer/partner relationship management (CRM/PRM) run across all of these segments.

All levels of service are provided, from warranty only to service packages including consulting, maintenance, and configuration. Sun creates and sells approximately 300 products per year, which are developed both on order basis and as standard products. For the most part, products are configured and shipped to order. The products have many variants and versions, which are constantly being updated and improved. The company sells hardware products independently from software products, and vice versa. Software is shipped via a fulfillment site (manufacturing) when it involves physical media and documents, or on-line via virtual distribution. Software products are also shipped bundled with hardware products.

8.2.1 Development process and PLC

Sun’s PLC process is one of its core business processes. It consists of four key process elements: structured process, product approval committees, product teams, and phase completion reviews. The PLC process governs cross organizational and cross-functional product development and PLC management activities. It also provides checklists that assure strong customer focus with increased product reliability and program execution predictability. The process is realized as a set of dedicated processes on top of a vault. It is integrated with many of the development tools, although it is not yet fully integrated.

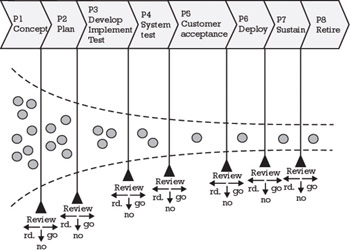

The structured process element of the Sun PLC process spans the entire PLC, from product concept to customer acceptance, and from product deployment to product retirement. It is articulated in eight distinct phases, which contain activities with associated deliverables and tasks that are used to clarify each activity. This process element provides guidelines for developing and sustaining products and enables consistent terminology and effective cross-functional and cross-organizational linkages. The structured process is divided in a sequence of eight phases, as shown in Figure 8.1.

![]()

Figure 8.1: The eight phases of Sun’s structured process.

The objectives of each phase are:

-

Concept. Explain the concept and key customer needs (e.g., critical to quality parameters), evaluate the market opportunity, assess product feasibility, and assess fit with company strategy.

-

Plan. Clearly define the product, develop technical approach and strategy, and plan the product development activities.

-

Develop/integrate and test. Develop and/or integrate product components, verify component performance, develop company’s and critical partners’ production processes, and prepare comprehensive plans for introduction, service, and support.

-

System test. Qualify the product functionality and performance and qualify production and supplier processes.

-

Customer acceptance. Confirm product functionality in planned customer environments and execute introduction and support plans.

-

Deploy. Launch the product. Stabilize operational, service, and support processes.

-

Sustain. Manage product profitability and growth, provide customer support and defect tracking, and plan product retirement.

-

Retire. Retire product and manage customer transitions.

A product approval committee (PAC) (see Figure 8.2) is a crossfunctional decision-making body within the process. Each PAC assures effective resource allocation and manages all development activities within a product line throughout the PLC process. At each phase completion, PAC makes go/no-go or redirect decisions.

![]()

Figure 8.2: Product approval committees.

Product teams are small, cross-functional teams representing the entire product program. Members of product teams assure effective communication and coordination and have program focus with clearly defined responsibility and authority to execute within the product plan (i.e., the contract). Each product team is lead by a product program manager whose rank is proportionate to the size/complexity of the program.

Phase completion reviews are event-driven reviews, conducted by PACs, which help maintain an effective pipeline of new products. These reviews are decision based (go—proceed, no go—terminate the program, and redirect—repeat the previous phase), as shown in Figure 8.3.

Figure 8.3: Phase completion reviews.

Key benefits of phase completion reviews are:

-

Provide a mechanism for early interventions that help reduce the unnecessary research and development spending;

-

Enable pipeline pruning, which is critical for optimizing the product portfolio;

-

Contribute to improved performance to plans because of frequent information exchanges;

-

Provide forum for cross-organizational resource management to minimize project delays;

-

Drive risk assessments and mitigations to increase probability of product successes.

In addition to the phase completion review, Sun uses program reviews during each phase to keep stakeholders informed about the progress within the PLC process.

Sun has designed its processes to be scalable both in terms of programs scope (i.e., program size) and program content type (i.e., systems products, software products, and hardware products). At the top process level, Sun treats all development programs the same, regardless of their program content type. Process differences that appear at the third and the fourth level of the process are dictated by specific needs of different product types or program scope.

8.2.1.1 Distributed development

There are many situations in which parts of products are designed and built in different locations. Distributed development is organized around the PLC process, its infrastructure, and its requirements. A key contribution of the PLC process to the effectiveness of the company is its overall architecture, which manifests itself in defined team structure, review requirements, management structure, and roles and responsibilities. For example, the PLC structured process requirements allow diverse geographic locations to have a common base upon which to standardize and operate consistently.

Internal deliveries of products or parts between geographically dispersed teams are done with the help of different tools. All of Sun’s employees have access to the same PLC information (as per a need-to-know basis) through applications available on the company network. For example, the Sun PLC process support application contains critical product information accessible by any team member at any location at any time. Also, conferencing tools enable team members anywhere to collaborate and work in a virtual team environment.

Sun utilizes a distributed development model for all product types. Because many of Sun’s products and components are shared by higher level products, part of Sun’s technical review structure is geared toward identifying economies of scale inherent in the reuse and sharing of components across products and product lines. Sun has developed processes that enable effective execution in such an environment. The software development subprocess specifically enables predictable product release schedules by virtue of identifying stable interfaces to which all components within products must comply at all times, regardless of their origin (i.e., either they are developed internally or externally). For example, in the event that a particular component undergoing changes suffers a schedule slip, the higher level release can still use the prior version of the component and will pick up the new component if it is ready on the next release cycle. This system allows Sun to maintain a fixed software release schedule at all times.

8.2.1.2 Change management

Product changes that result from customer-identified issues are categorized (e.g., bugs/defects and feature requests) and scheduled for action according to level of severity. Sun regularly releases patches and product upgrades to address such issues. In addition, new feature work is integrated into a development planning process so that it can be delivered within an established release schedule.

One of Sun’s major achievements is a complete backward binary compatibility of its microprocessors and operating system. They were able to achieve this because of good component interface management and management of product architecture.

8.2.1.3 Tool support for the development process

As mentioned earlier, Sun currently manages the PLC process through a dedicated process support application. All product development teams are required to use this application regardless of the product type. In general, product teams manage and archive through this application the PLC process specified deliverables, such as market requirements documents, product requirement documents, product concept documents, functional specifications, product plans, product boundary and summary, design schematics, and software code. Sun also uses intranet tools to manage financial data, BOMs, factory-level execution, inventory controls, part number registry, ECM process, and document management. In addition, Sun’s product development organizations use numerous CAD and other eEngineering tools.

Mostly Sun uses the same tools within development and manufacturing processes, although a few gaps remain. Currently, Sun is evaluating the cost and benefit of integrating several applications, such as portfolio management, requirements management, collaboration, PDM, and materials sourcing in an integrated PLM system, which is aimed to assure complete integration of product development information and systems across the enterprise.

In addition to the PLC process tools, software development is managed through SCM tools. General requirements on software management include support for concurrent development (such as branch and merge), version management, build management, workspace management, and history management.

Although Sun can monitor progress of all product devolvement using the PLC process support tool, they recognize an overlap between the information in the different process support tools (e.g., PLC, PDM, and SCM). In fact, this is one of the drivers behind the initiative to deploy an integrated PLM system.

8.2.2 Deployment of tools

Sun usually develops and/or updates key processes first and subsequently deploys process support tools to the user base. For example, the PLC process support application was deployed companywide together with the rollout of the PLC process improvements. Sun experienced some difficulties with the acceptance of these tools, which is typical for the introduction of complex tools (see Chapter 6). To assure success, Sun dedicates a substantial amount of effort to manage required cultural changes. Cultural change management is an integral part of any large initiative, and Sun has gained a substantial experience doing that both with PLC and Six Sigma deployment, which they call SunTM Sigma.

8.2.3 Conclusion

Sun sees the following four areas as key advantages of using PLM, PDM, SCM, and document management tools:

-

Automation provides huge opportunity for improved transactional efficiency.

-

Common data and search functionality enables more effective reuse of design knowledge.

-

Effective architectural, technical, and phase completion reviews assure better utilization of resources and guarantee lower cost of quality.

-

Overall increased efficiency yields better time to market, which in turns enables the capture of higher revenue and assures better margins.

More about hardware and software PLC processes and the importance of information integration during these processes can be found in Chapter 5.

[1]CXO is an acronym for a member of top-level management. The “X” is a variable so the term can stand for chief information officer (CIO), chief financial officer (CFO), chief executive officer (CEO), and so on.

|

| < Day Day Up > |

|

EAN: 2147483647

Pages: 122

- Using SQL Data Manipulation Language (DML) to Insert and Manipulate Data Within SQL Tables

- Working with Comparison Predicates and Grouped Queries

- Writing External Applications to Query and Manipulate Database Data

- Retrieving and Manipulating Data Through Cursors

- Exploiting MS-SQL Server Built-in Stored Procedures