Extreme Overclocking of Processors

|

| < Day Day Up > |

|

For extreme overclocking of processors, characterized by extremely high values of clock frequencies, it is often necessary to increase the core supply voltage considerably. These processes are accompanied by exceedingly high heat emission. If the heat is never dispersed from the processor chip, the heat balance required for correct operation of the core will be disrupted. Furthermore, the uneven workloads on internal structures and units of the processor, as well as their different operating frequencies, make the heating and heat emission of different core areas uneven.

High temperatures of specific internal structures of the CPU chip limit the range of clock frequency growth. Besides this, high temperatures speed up semiconductor decay, which greatly reduces the processor durability. In addition, the processor becomes less stable, which influences overall system stability. Undesirable processes, even those that take place in recommended operating modes, significantly increase and speed up in extreme overclocking modes.

A powerful and efficient cooling system can help to withstand some decay in semiconductors. Such a cooling system can ensure acceptable conditions for the processor operation, even in the course of extreme overclocking.

Under conditions of extreme overclocking, the heat emission of the processor is so high that heat balance based on air-cooling support becomes inadequate. Liquid-cooling systems based on water are also unable to solve this problem. Water has the highest heat capacity of the natural substances that remain liquid in temperatures acceptable for semiconductors. Using water for cooling under normal conditions, including moderate overclocking, ensures efficient heat transmission from the hot chip to the heatsink equipped with a fan. Still, even a water-cooling solution cannot ensure the temperature required for extreme overclocking.

The inefficiency of traditional cooling methods in extreme overclocking modes is related to the overheating of the internal circuitry of the processor chip. Extra heat emitted from these areas likely will disrupt the operation of complex semiconductor circuits. Local overheating can even destroy these circuits. Under these conditions, semiconductors are unable to function. Traditional cooling facilities cannot always evacuate this heat efficiently, especially because of the limited thermal conductance of silicon (or any other material).

However, the value of heat flux, defined as the amount of heat passed per time unit, is proportional to the temperature gradient:

This means that the rate of heat transfer depends on the temperature difference between the heating zone and cooling zone. To ensure efficient cooling under conditions of extreme overclocking, it is best to use cryogenic temperatures at the surface of the cooled chip.

Normal ice can be used as cooling substance; melting heat — the energy produced by a transition from a solid state to a liquid state — is rather high. This circumstance ensures that relatively little ice will be needed during experiments. However, its melting temperature is only 0°C (32°F), which doesn't ensure high values of heat flux. Ice can be used in experiments in the field of extreme overclocking, but it is unlikely that high results would be achieved in such experiments.

The best temperature parameters are characteristic for so-called dry ice, or solid-state carbon oxide. Its temperature of phase transition is -70°C (-94°F). This, compared to normal ice, ensures far better values of heat flux. However, for carbon oxide, the temperature of phase transition into the gaseous state is much lower than the melting temperature of normal ice. This means more dry ice will be required for extreme overclocking experiments.

Liquid nitrogen is a more promising cooling substance because its boiling temperature is close to -196°C (-320°F). However, its phase-transition energy is very low. As a result, the heat absorbed during evaporation of this substance is also very low. To cool powerful processors characterized by high values of heat generation, large amounts of liquid nitrogen will be required. Despite these difficulties, it was liquid nitrogen that allowed research groups in many countries to achieve good results in extreme overclocking of standard processors.

Specific features and experimental results in the field of extreme overclocking of processors are provided in the following sections.

Extreme Overclocking of Intel Processors

(With the permission of http://www.overclockers.ru, a Russian-language Web site.)

Liquid nitrogen has become the chosen cooling agent for extremely overclocked processors because it has an exceedingly low evaporation temperature. The large difference between the temperatures of evaporating nitrogen and the CPU surface produces an intensive heat exchange that efficiently cools the overclocked CPU.

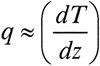

The use of liquid nitrogen required nonstandard facilities to play the role of processor cooler. To achieve this goal, researchers created a special container for nitrogen, installed on the top of the processor. This container was made from copper, the material with the best thermal conductance, after silver (which, unfortunately, is too expensive).

The cooling container could have been manufactured by soldering (from sheet copper), drilling (one piece of copper), or welding.

A stannic (tin) solder has never been recommended for such purposes, because standard solders of this type form unstable compounds at cryogenic temperatures. At temperatures below -40°C (-104°F), tin turns into mechanically unstable modification. Besides this, such a construction has lower thermal conductance than one manufactured from pure copper. This is because tin and its alloys have high thermal resistance. Another solution, which would require a container made from a solid piece of copper, was free from this drawback. Still, a large piece of expensive copper would be required, and most of this copper would be wasted. Furthermore, to manufacture this detail in such a way, special instruments would be required.

Therefore, the third method was chosen. Elements of the container were joined using electron-beam welding. During this technological process, the parts to be connected were heated to the required temperature by the beam of electrons sped up to a high speed. The bond obtained using this method was rather strong. In addition, the residual stresses that remained in the material after the welding operation were minimal, which ensured high strength under drastic temperature changes and no geometric distortions of the cooling container due to geometrical skew.

The dimensions of the cylindrical cooling container were chosen as follows:

-

Height — 300 mm

-

Diameter — 50 mm

-

Thickness of walls — 2 mm

-

Thickness of bottom — 3 mm

This construction was installed on the processor and fastened using metal rods with screws and nuts. The container was pressed against the board using an additional plate of metal. This means that on one side, the rods were screwed into the motherboard, which has special holes for fastening coolers, and on the other side, they were fastened to the metallic plate that pressed the cooling container against the processor.

The process of fastening this cooling system was as follows:

-

The copper cooling container was installed on an Intel Pentium 4 processor.

-

Metal rods with the appropriate screws were screwed into the holes in the motherboard and were fastened with nuts.

-

From above, the container was pressed against the board using a plate of aluminum, which had a hole in the center and several holes for fastening rods at its sides.

-

The rods were set into the holes, and the entire construction was fastened with nuts screwed from above.

-

A funnel made of stainless steel was installed into the central hole.

Figure 3.14: Cooling system for extreme processor overclocking (assembled)

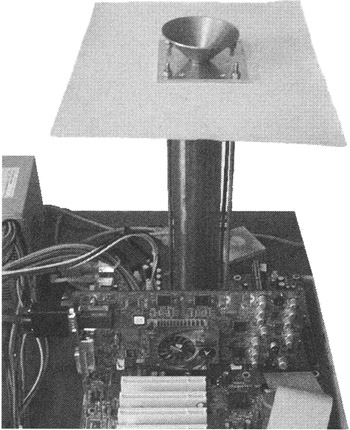

Figure 3.15: Filling the cooling system with liquid nitrogen

After some time, a computer equipped with this cooling system stopped booting normally. The problem was related to condensation: A large amount of water accumulated near the processor slot. In the course of cooling, pieces of frozen condensate fell from the cooling container. On the motherboard, they melted and produced water. In other places on the motherboard, the water appeared because of the intense boiling of nitrogen, during which some drops fell on the motherboard. As a result, water appeared in cool regions of the motherboard.

Ice crystals falling from the copper cooling container caused another serious problem. This problem was solved using a normal household fan. A stream of air, directed from this fan toward the cooling container, diverted all crystals that otherwise would have fallen on the motherboard. However, because the fan blew a large amount of air around the cooling container, it increased the thickness of the frost that covered the cooling container. This layer was rather dense, and it didn't fall onto the motherboard.

As for the problem of water, it was solved by placing a sheet of foam rubber below the motherboard.

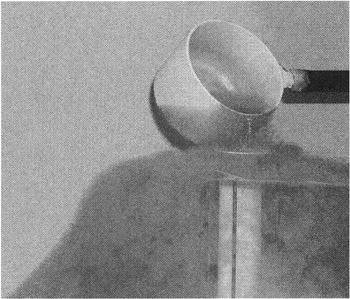

Figure 3.16: Ice-crystal layer on the copper cooling container

Figure 3.17: Motherboard covered with frost

Later, another method was found to help solve the problem of condensation. The basic idea of this method was as follows: The entire motherboard was covered evenly with liquid nitrogen. As a result, the entire motherboard was cooled below the freezing point of water, and ice caused significantly less harm to the motherboard.

These steps ensured stable operation of the system in the extreme overclocking mode of the processor. Of course, this could occur only if the cooling container contained liquid nitrogen and, consequently, if it ensured constant cooling of the processor.

Configuration of the Test System

Processors:

-

Intel Celeron 1.8 GHz

-

Intel Pentium 4 2.2 GHz

-

Intel Pentium 4 2.4 GHz

-

Intel Pentium 4 2.53 GHz

Motherboard:

-

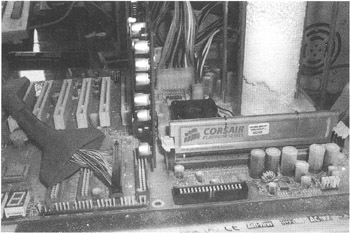

Epox 4BDA

RAM:

-

Corsair XMS3000

Video adapter:

-

VisionTek GeForce4 Ti4600

Software:

-

Windows XP Professional/2000 Professional SP1

-

Nvidia Detonator 29.42

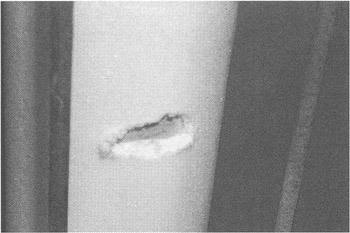

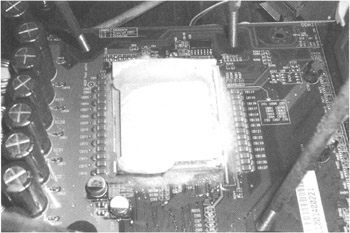

Researchers had to abandon thermal paste. At the temperature of liquid nitrogen, it would freeze. As a result, the CPU surface would be covered with a layer of ice, which would decrease heat exchange considerably. The cooling container also would freeze to the processor's surface. Therefore, a long time would be required to replace the processor. Because of this, a cooling container often was installed on a heat-dissipating plate, the Integrated Heat Spreader (IHS) of Intel Celeron and Intel Pentium 4 processors, without thermal paste.

Figure 3.18: Frozen thermal paste on the heat-dissipating plate of the processor

Extreme Overclocking of Celeron Processors

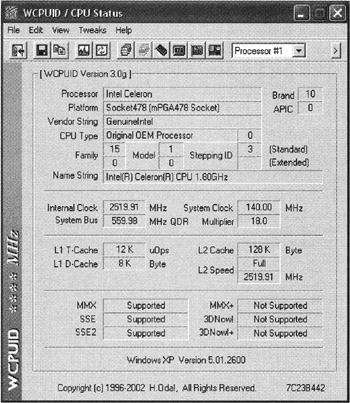

Overclocking can be accomplished by increasing the FSB clock frequency while increasing the CPU core voltage (Vcore) to the maximum allowed by the motherboard. At a core voltage of 1.85 V, stable operation could be ensured at FSB frequencies to 140 MHz. This would result in a CPU frequency of 2,520 MHz (Fig. 3.19).

Figure 3.19: Parameters of Intel Celeron 1.8 GHz overclocked to 2,519.91 MHz

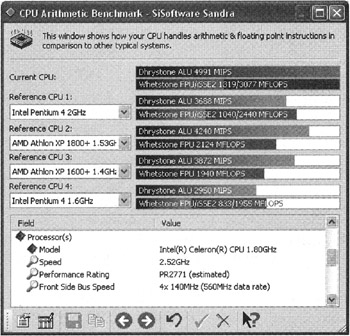

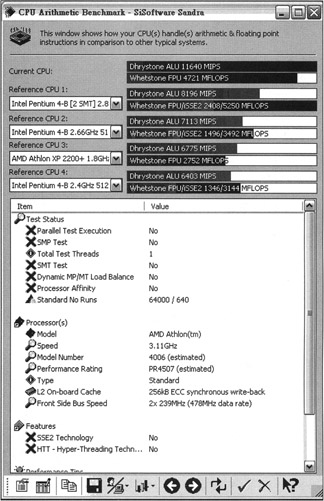

Several tests were performed for this mode. Test results obtained using SiSoftware Sandra are in Fig 3.20.

Figure 3.20: Results of testing the overclocked CPU using SiSoftware Sandra

Extreme Overclocking of Pentium 4 Processors

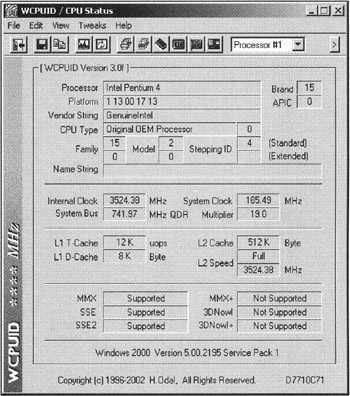

Extreme overclocking of Intel Pentium 4 processors can be achieved by raising the FSB clock frequency at the core voltage of 1.85 V. As in the previous case, cooling was performed using liquid nitrogen. In the course of extreme overclocking, all CPU models exceeded the level of 3 GHz. The best result was achieved by the Intel Pentium 4 processor intended to run at 2.53 GHz. Being cooled by liquid nitrogen, this processor showed stable operation at a bus frequency of 185 MHz. Under conditions of the fixed multiplier value, this ensured the resulting clock frequency of 3,524 MHz.

Figure 3.21: Parameters of Intel Pentium 4 2.53 GHz overclocked to the maximum frequency of 3,524.38 MHz

In experiments on extreme overclocking using liquid nitrogen conducted by another group of researchers (see http://holicho.lib.net, a Japanese Web site), the Intel Pentium 4 processor intended to run at 3.06 GHz was successfully overclocked to 4.6 GHz. In these experiments, the FSB frequency equaled 200 MHz. Thus, one of the most powerful Intel processors implementing the NetBurst architecture, manufactured using 0.13-micrometer technology, was overclocked 1.5 times.

In extreme overclocking experiments, researchers used the Gigabyte 8INXP motherboard based on the Granite Bay (E7205) chipset. To achieve high results, the CPU core voltage was increased to 2.1 V. Because the motherboard doesn't support such voltage levels, the voltage was raised using its hardware modification.

Figure 3.22: Parameters of Intel Pentium 4 3.06 GHz overclocked to 4,599.85 MHz

This example can be used to partially predict the performance of future processors with a clock frequency of 4.6 GHz and a bus frequency of 800 MHz. Such frequencies can be achieved only by the Prescott core, which has 1 MB of L2 cache memory manufactured using 0.09-micrometer technology.

Note that Intel processors are not exceptions. A similar procedure of extreme overclocking is applicable to AMD products. Materials from a range of sites (see Chapter 19) serve as evidence of this.

Extreme Overclocking of AMD Processors

Extreme overclocking of AMD processors in systems with liquid nitrogen cooling has its own specific features. AMD products have no heat-dissipating plate similar to IHS on Intel processors; therefore, with AMD products, there is a high risk of causing mechanical damage to the core. Besides this, the lack of the even, smooth, and large area formed by heat-dissipating plate creates additional difficulties when ensuring even contact of the cooling container and the processor. On the other hand, the lack of this plate can have a positive effect on the cooling quality, because there will be only one transition (core — cooling container) instead of two transitions (core — IHS — cooling container).

Extreme Overclocking of Athlon XP 1700+ Processors

Well-known overclocker YAO (see http://www.piopioshardware.com, a Chinese Web site) accomplished extreme overclocking of the AMD Athlon XP 1700+ processor by increasing the multiplier and EV6 processor bus.

The system operated at the following increased voltages:

-

CPU core voltage (Vcore)

-

North Bridge voltage (Vdd)

-

RAM modules supply voltage (Vdimm)

The processor was cooled using liquid nitrogen; for the North Bridge chip, water cooling was used.

Configuration of the Test System

Processor:

-

AMD Athlon XP 1700+ (Marking = AXDA1700DLT3C JIUHB0309UPMW, clock frequency = 1,467 MHz, FSB frequency = 266 MHz, L2 cache = 256 KB, Vcore = 1.5 V)

Motherboard:

-

Epox EP-8RDA+, Rev.1.1, BIOS 3305

RAM:

-

A-Data DDR400, 256 MB, 2.79 V (3-2-2-2.5 1CMD) × 2

Video adapter:

-

Albatron MX420 (GeForce4 MX420)

Hard disk:

-

Quantum (20 GB, 7,200 rpm).

Power supply unit:

-

SevenTeam ST-300BLV

Driver:

-

Nvidia nForce Driver 2.3, Nvidia Detonator 42.86

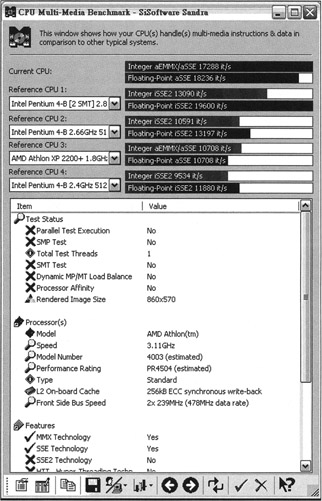

As a result, the processor was overclocked to the frequency of 3,107 MHz, at a multiplier raised to 13x and a system bus frequency increased to 239 MHz. The voltage at the North Bridge chip was increased to 1.92 V using the hardware modification of the motherboard. RAM voltage was raised to 2.79 V; the CPU core voltage reached 2.016 V.

Figure 3.23: Parameters of AMD Athlon XP 1700+ overclocked to 3,107.05 MHz

Figure 3.24: Results of Dhrystone and Whetstone benchmark AMD Athlon XP 1700+ overclocked to 3,107.05 MHz

Figure 3.25: Integer and floating-point results of testing AMD Athlon XP 1700+ overclocked to 3,107.05 MHz

Figure 3.26: RAM results of testing AMD Athlon XP 1700+ overclocked to 3,107.05 MHz

The performance of the AMD Athlon XP 1700+ processor overclocked to 3,107.05 MHz and cooled using liquid nitrogen can be evaluated according to the test results shown by SiSoftware Sandra.

| Tests | Results for Athlon XP 1700+ (3,107.05 MHz) | Results for Pentium 4 2.8 GHz |

|---|---|---|

| Dhrystone ALU (MIPS) | 11,640 | 8,196 |

| Whetstone FPU (MFLOPS) | 4,721 | 2,408 5,250 (SSE2) |

| Integer aEMMX/aSSE (it/sec) | 17,288 | 1,3090 (SSE2) |

| Floating-point (it/sec) | 18,236 | 1,9600 (SSE2) |

| RAM integer buffered aEMMX/ aSSE bandwidth (MB/sec) | 3,691 | 2,937 (SSE2) |

| RAM floating-point buffered aEMMX/aSSE bandwidth (MB/sec) | 3,520 | 2,940 (SSE2) |

As a result of extreme overclocking of the AMD Athlon XP 1700+ processor, its clock frequency (1,467 MHz) was increased 112% to 3,107 MHz. This corresponds to a rating of 4000+.

To conclude, it is necessary to emphasize that the results of extreme overclocking provided here were achieved only because of the art of overclockers and researchers, who used cryogenic cooling. These systems and methods are not suitable for home usage. Nevertheless, these data are interesting; they demonstrate the potential of modern computer technologies. The results provided in these experiments can be used to predict the potential of future products.

|

| < Day Day Up > |

|

EAN: 2147483647

Pages: 111