MOTOROLA S 6 SIGMA

MOTOROLA'S 6 SIGMA

In the previous section, we defined a k-sigma process as one in which the distance from the target to either specification limit is k ƒ . Until the 1990s, most companies were very content to achieve a 3-sigma process, that is, C p = 1. Assuming that each part's measurement is normally distributed, companies reasoned that 99.73% of all parts would be within specifications. Motorola questioned this notion on two counts:

-

Products are made of many parts. The probability that a product is acceptable is the probability that all parts making up the product are acceptable.

-

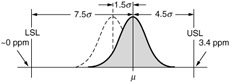

When using control charts to monitor quality, shifts of 1.5 standard deviations or less in the process mean are difficult to detect. Therefore, when we are producing a product, there is a reasonable chance that the process mean will shift up or down by as much as 1.5 ƒ without being detected (at least in the short run). A shift to the right is shown in Figure 12.24. The reader should note that the shift could also be to the left.

Figure 12.24: A process with a 1.5-sigma shift to the right.

Given that the process mean might be as far as 1.5 ƒ from the target and that a product is made up of many parts, a 3-sigma process might not be as good as we originally stated. Just how good is it?

Suppose that a product is made up of m parts. We will calculate the probability that all m parts are within specifications when the process mean is 1.5 ƒ above the target and the distance from the target to either specification limit is k ƒ . That is, we are considering a k-sigma process with a process mean off center by an amount 1.5 ƒ . Let X be the measurement for a typical part, and let p be the probability that X is within the specification limits; that is, p = P (LSL < X < USL). If p m is the probability that all m parts are within the specification limits, then assuming that all parts are identical and probabilistically independent, the multiplication rule for probability implies that p m = p m .

To calculate p = P (LSL < X < USL), we need to standardize each term inside the probability by subtracting the process mean ¼ and dividing the difference by ƒ . Let T be the target. Then we have LSL = T - k ƒ and USL = T + k ƒ (because the process is a k-sigma process) and ¼ = T + 1.5 ƒ (because the mean has shifted upward by an amount 1.5 ƒ ). Therefore, the standardized specification limits are

This implies that

p = P ( -k -1.5 < z < k - 1.5) = P ( z < k - 1.5) - P ( z < -k - 1.5)

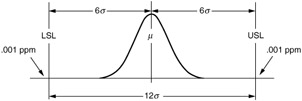

When this is actually carried out with a software package, one finds that for many applications a 3-sigma process is inadequate, having about 7% of its individual parts out of specifications. In contrast, a 6-sigma process is extremely capable, with only 0.34% of its 1000-part products out of specifications. No wonder Motorola's 5-year goal (as of 1992) was to achieve "6-sigma capability in everything we do." This is remarkable quality! The concept of the 6-sigma quality is shown in Figure 12.25.

Figure 12.25: A process with potential capability of 12 sigma equaling the tolerance.

The above analysis shows how we can calculate the capability of a process if we know that it is a k-sigma process for any specific k. We conclude this section by asking a slightly different question. If a company has produced many parts and has observed a certain fraction to be out of specifications, what is their estimated value of k? For example, suppose that after monitoring thousands of gaskets produced on its machines, a company has observed that 0.545% of them are out of specifications. Is this company's process a 3-sigma process, a 4-sigma process, or what?

To answer this question, we assume a worst-case scenario in which the mean is above the target by an amount 1.5 ƒ . Then, from the above equation, we know that the probability of being within specifications is

p = P ( Z < k - 1.5) - P ( Z < -k - 1.5)

if the process is a k-sigma process. However, we now know p from observed data, and we want to estimate k. This can be done with many software packages. In this case, it turns out that the value of k is 4.077.

EAN: 2147483647

Pages: 181