Chapter 16: Readership and Form

|

16.1 Which Comes First? The Manual, the Processes, or the Procedures?

We want to make sure that our QMS creation model is complete. For example, we have seen that the creation of the ISO 9000 documentation system is an iterative process whereby each document tends to support other documents. As a result, the question arises as to which document to create first.

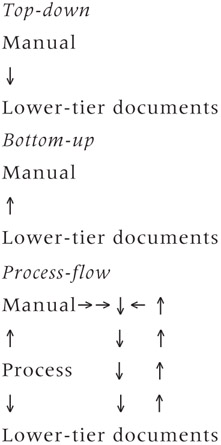

There are several ways to approach this question, and all three approaches will have some percentage of the others in practice:

-

Top-down method—Begin with the manual's quality policy statements and then create the lower tier documents.

-

Bottom-up method—Work from the set of lower tier documents to create the quality policy statements in the manual.

-

Process-flow method—Start with a flow analysis of the organization's processes and create the manual and lower tier documents concurrently. The methods used to create the flow analysis include flow charts and a tabular flow of activities. This is an iterative process. However, the flow analysis ensures consistency between the various documentation levels and minimizes redundancy, especially between the policy statements and the procedures.

Alert: If flow charts are chosen for the flow analysis, be sure that there is compatibility among the computer systems and that enough expertise is available to program the flow charts and modify them.

Table 16.1 indicates which method might be the most effective for a given size organization with a given degree of documentation maturity.

| Method | Suggested Applications | Comments |

|---|---|---|

| | Small organizations with minimal documentation, such as Metrology Laboratory or Component Repair Co. Large organizations with readily available mature documentation systems that were originally based on Mil-Q-9858A or standards Appropriate for all types of organizations Generally by means of a flow chart or flow table Found to be the most effective method for explicit organizational knowledge | Tendency to stress policy over procedure—but this does not have a great impact because on-the-job-training is prevalent Little opportunity to streamline the existing system Redundancy and obsolescence needs to be looked at in detail Tends to minimize total document quantity Exposes weaknesses in operational activities Readily catches the most frequently found gap—the handshake from department to department Most expeditious for ISO 9001:2000 manual creation |

We have observed all of these methods in practice to some degree and believe that the most effective approach overall is to begin with an analysis of the organization's processes first (i.e., the process-flow method) [1].

[1]The reader may feel that there is a conflict between the use of process analysis as the first element of system design and the belief that the first major gate in system development is the manual. We maintain that when we begin with process and then use that information as a database to define our quality policy statements, the policies end up with greater credulity and usefulness. The process documents act as the baseline research tools and the quality policy manual acts as the system controller. There appears to be some agreement in this area (i.e., McLymont, Rosalind, and Amy Zukerman, "Slipping into ISO 9000:2000," Quality Digest, August 2001, p. 30, at http://www.qualitydigest.com.

|

EAN: 2147483647

Pages: 155