16.2 Par. 4.2.1 of the Standard

|

16.2 Par. 4.2.1 of the Standard

The Standard does imply a form of style. This is found in Par. 4.2.1: General Documentation Requirements, Note 2, which advises us that QMS documentation can vary considerably between organizations due to differences in size, complexity, and personnel, among others. This is a very powerful note because it implies that the Standard allows the organization to custom fit the documentation to the organization's sophistication and complexity. Certainly, a design engineer requires more guideline than procedure, whereas an assembler requires more procedure than guideline.

Although it seems intuitively obvious, it's worth stating the following:

-

Design engineers require primarily guidelines.

-

Experienced machinists need a minimum of procedures.

-

Test operators need more detailed process sheets to properly perform their functions.

It is common, for example, to find engineering documents at a level of detail that is literally overwhelming. This issue can be effectively resolved by use of a controlled one-page flow diagram that references the key design documents. This becomes a handy wall reference chart for the project engineer. It's also common to find tier II and related tier III documents that contain nearly 50% of the same text. However, on the first final edit, it is better to be cautious so that the baby is not thrown out with the bath water. We maintain

-

A little long,

-

May be too strong,

-

But it ain't wrong.

-

Terse is worst!

16.2.1 Linear Estimate

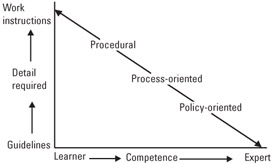

At the risk of oversimplification, we offer a rule with regard to necessary detail (see Figure 16.1). The rule assumes a linear function that is certainly not what you normally find, but it should clarify the point.

Figure 16.1: Documentation rule to "consider the reader."

Notice that more training is usually required as the subtlety of the documentation context expands (e.g., the ability to understand work instructions versus policy statements). The more expert the reader, the more guidelines make sense. The less expert the reader, the more highly detailed work instructions make sense.

There is a flip side to this concept. Work instructions are always required, no matter what the reader's competence level, when it comes to detailed test or laboratory instructions.

16.2.2 Conclusion

We do not imply that everyone needs to be a great writer—it is unclear how to define such a concept. But it is within each author's ability to stress clarity and to simplify concepts. If your text looks long and cluttered, it is. If your key ideas do not show up against the background of words, they are lost. Clear exposition is based on some basic rules, but it is also based on intuition and common sense.

A way to produce an effective document is as follows:

-

Start with one rough draft.

-

Undergo two subsequent editorial reviews with the document users before document control is initiated.

-

Going to document control too early is an enormous waste of time and energy. Later is better.

-

Some companies do not place their documents under control until just prior to the readiness (preassessment) audit.

For most companies, there will exist a strong tier III and tier IV set of documents already available, especially if they have a basic quality system in place based on a TQM or Food and Drug Administration-driven set of requirements. The biggest issue is to integrate the tier I and tier II documents into this pool of readily available documents and then fine tune the entire set to make them consistent and effective.

Our observations in well over 100 organizations have indicated that when the manual is written for the customer, and especially for the new customer—in a clear, concise manner, filled with specific information for decision makers—it is an effective document for all other readers.

|

EAN: 2147483647

Pages: 155

- Chapter VI Web Site Quality and Usability in E-Commerce

- Chapter VII Objective and Perceived Complexity and Their Impacts on Internet Communication

- Chapter VIII Personalization Systems and Their Deployment as Web Site Interface Design Decisions

- Chapter XII Web Design and E-Commerce

- Chapter XV Customer Trust in Online Commerce