Heat Problems and Cooling CPUs

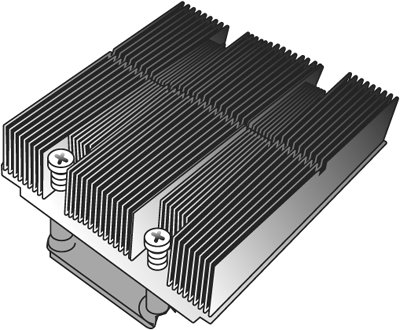

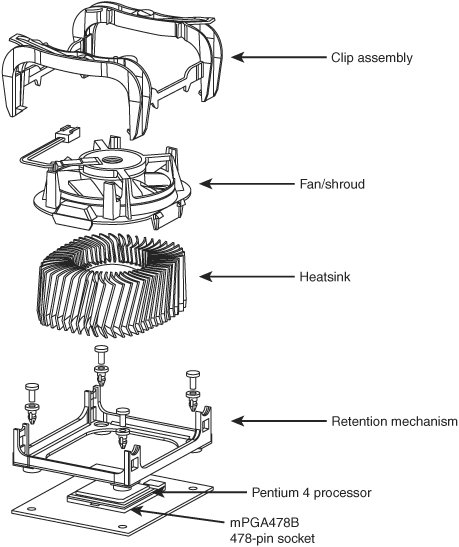

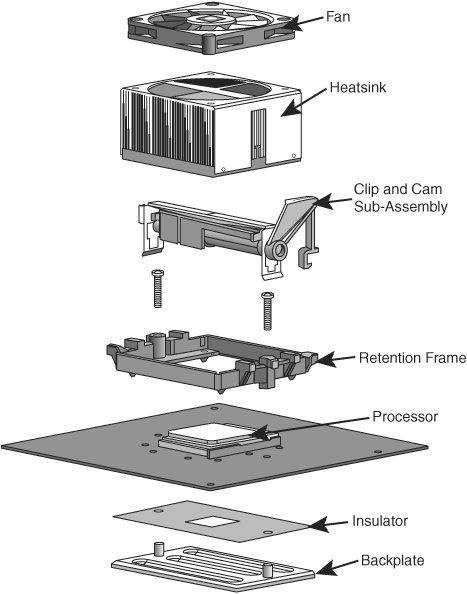

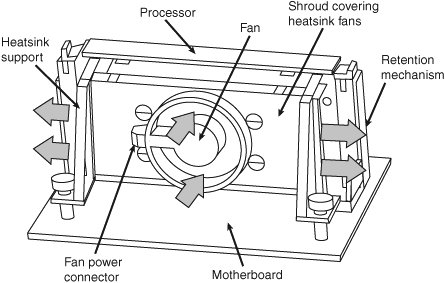

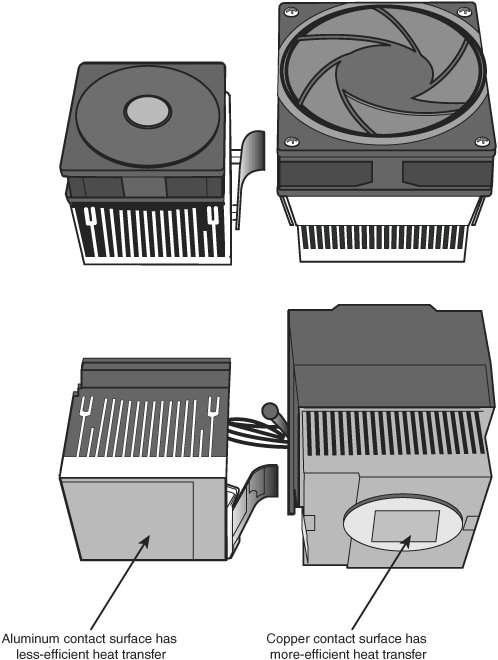

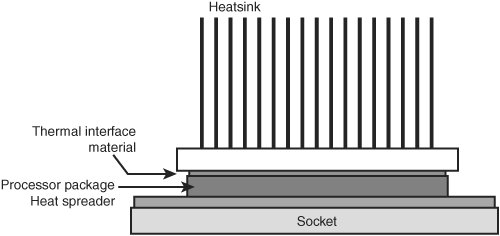

| Heat can be a problem in any high-performance system. Higher-speed processors consume more power and therefore generate more heat. The processor is usually the single most power-hungry chip in a system, and in most situations, the fan inside a computer case is incapable of handling the load without some help. HeatsinksAt one time, a heatsink, a special attachment for a chip that draws heat away from the chip, was needed only in systems in which processor heat was a problem. However, heatsinks have been a necessity for every processor discussed in this book. Several heatsink manufacturers are listed in Appendix C, "Vendor List." A heatsink works like the radiator in a car, pulling heat away from the engine. In a similar fashion, a heatsink conducts heat away from the processor so it can be vented out of the system. It does this by using a thermal conductor (usually metal) to carry heat away from the processor into fins that expose a large amount of surface area to moving air. This enables the air to be heated, thus cooling the heatsink and the processor as well. Just like the radiator in a car, a heatsink depends on airflow. With no moving air, a heatsink is incapable of radiating the heat away. To keep the engine in a car from overheating when the car is not moving, auto engineers incorporate a fan. Likewise, there is always a fan somewhere inside a PC, helping to move air across the heatsink and vent it out of the system. In some name-brand systems, the fan included in the power supply is enough when combined with a special heatsink design; in most cases, though, an additional fan must be attached directly over the processor to provide the necessary level of cooling. Case fans are also typical in recent systems to assist in moving the hot air out of the system and replacing it with cooler air from the outside. Tip According to data from Intel, heatsink clips are the number-two destroyer of motherboards (screwdrivers are number one). When installing or removing a heatsink that is clipped on, be sure you don't scrape the surface of the motherboard. In most cases, the clips hook over protrusions in the socket, and when installing or removing the clips, it is very easy to scratch or scrape the surface of the board right below where the clip ends attach. It's a good idea to place a thin sheet of plastic underneath the edge of the clip while you work, especially if board traces that can be scratched are in the vicinity. Heatsinks are rated for their cooling performances. Typically, the ratings are expressed as resistance to heat transfer, in degrees centigrade per watt (°C/W), where lower is better. Note that the resistance varies according to the airflow across the heatsink. Passive HeatsinksPassive heatsinks are basically aluminum-finned radiators that rely on airflow from an external source. Passive heatsinks don't work well unless there is some airflow across the fins, usually provided by a chassis-mounted fan that sometimes features a duct to direct airflow directly through the fins on the heatsink. Integrating a passive heatsink is difficult because you must ensure that the airflow comes from some other source; however, this can be very reliable and very cost-effective if done correctly. Some tower, pedestal, and rack-mounted chassis from major vendors such as Intel are designed to use passive heatsinks with one or more ducted chassis fans. Figure 2.30 illustrates an aftermarket passive heatsink designed for a Xeon processor installed in a 1U rack-mounted server. It uses copper fins to provide adequate cooling, using the internal fans of the chassis that blow air past the motherboard's components. Figure 2.30. A low-profile passive heatsink for a Xeon, optimized for a 1U rack-mounted server. Active HeatsinksIf you are building your own server or if you are using very fast processors, you will probably use active heatsinks on your processor(s). An active heatsink provides a more certain cooling solution, regardless of other airflow characteristics in the system. To ensure a constant flow of air and more consistent performance, many heatsinks incorporate fans so they don't have to rely on the airflow within the system. Heatsinks with fans are referred to as active heatsinks (see Figure 2.31). An active heatsink has a power connection. Older heatsinks often used spare disk drive power connectors, but most recent heatsinks plug in to dedicated heatsink power connections found on the newer motherboards. Figure 2.31. An active heatsink suitable for a Pentium 4 processor using Socket 478. Tip One of the best reasons to use the motherboard-based power connectors for the fan is that most recent system BIOS Setup programs can display the fan performance and report it to a system monitoring program. The BIOS or a system monitoring program can shut down the system if the fan fails or if its RPMs drop below a specified value. This helps prevent processor damage. On systems with a processor that supports thermal throttling, this feature can also be used to slow down the processor to avoid overheating. The Pentium 4 design shown in Figure 2.31 uses two cams to engage the heatsink clips and place the system under tension. The force generated is 75 pounds, which produces a noticeable bow in the motherboard underneath the processor. This bow is normal, and motherboards are designed to accommodate it. The high amount of force is necessary to prevent the heavier heatsinks from pulling up on the processor during movement or shipment of the system, and it ensures a good bond for the thermal interface material (thermal grease). Figure 2.32 shows the design used on most AMD Opteron processors, featuring a cam and clip assembly on one side. Similar to the Pentium 4 double-cam assembly shown earlier in Figure 2.31, this design puts 75 pounds of force between the heatsink and the processor. Bowing of the motherboard is prevented in this design through the use of a special stiffening plate underneath the motherboard. The heatsink retention frame actually attaches to this plate through the board. The stiffening plate and retention frame normally come with the motherboard, but the heatsink with fan and the clip and cam assembly are included with the processor. Socket 939 and Socket 940 processors use similar designs. Figure 2.32. An active heatsink suitable for an Athlon 64, Athlon 64 FX, or Opteron processor using Socket 754, Socket 939, or Socket 940. Figure 2.33 shows an active heatsink arrangement on a slot-based Pentium II/III processor. Figure 2.33. An active (fan-powered) heatsink and supports used with cartridge-type Pentium II/III processors. With the wide variety of processor speeds and construction on the market today, you also need to match the processor speed to the speed range of the heatsink you plan to use. Heatsinks made for faster processors have a larger cooling area, and an increasing number of them use a copper conducting plate or are made of solid copper rather than less-conductive aluminum. Figure 2.34 compares two heatsinks made for Athlon MP processors. Figure 2.34. The all-aluminum active heatsink at left is designed for slower processors than the copper/aluminum model at right. Note Some Pentium 4 Socket 775 processors are sold in two forms: Some are packaged with a cooling solution suitable for ATX motherboards, and others are packaged with a cooling solution suitable for BTX motherboards. See Chapter 4, "Server Motherboards and BIOS," for more information about the differences between ATX and BTX motherboards. Processors sold as boxed or retail versions from Intel and AMD include high-quality active heatsinks designed to work under the worst possible ambient conditions. One of the main reasons to purchase boxed processors for systems that use standard motherboards is that you are guaranteed to get a high-quality heatsink with the processor, one that is designed to cool the processor under the worst conditions and that should last the life of the system. Factory-boxed processors also have long warranties that are valid only if you use the vendor-provided heatsink. Blade Server CoolingDepending on the product you use, the processors in your blade server might be cooled using passive coolers with very high-performance fans or more exotic technologies such as vapor cooling, which uses liquid inside a finned cooler to vaporize and transfer heat away from the processor. Blade server vendors usually require you to purchase the appropriate cooling solution when you purchase a new blade. You can help minimize heat concerns by specifying lower-voltage versions of processors such as the Xeon and Opteron for your server blades and by adding additional air conditioning to your server room. Heatsink Ratings and CalculationsTo cool a processor, a heatsink transfers heat from the processor to the air. This capability is expressed in a figure known as thermal resistance, which is measured in degrees Celsius per watt (C/W). The lower the figure, the lower the thermal resistance and the more heat the heatsink can remove from the CPU. To calculate the heatsink required for your processor, you can use this formula: Rtotal = Tcase - Tinlet/Ppower Tcase is the maximum allowable CPU case temperature, Tinlet is the maximum allowable inlet temperature to the CPU heatsink, and Ppower is the maximum power dissipation of the processor. For example, the Pentium 4 3.4E (Prescott) processor is rated for a maximum operating temperature of 73°C and a maximum heatsink inlet temperature of 38°C, and it has a maximum thermal output of 103 watts. This means the heatsink required to properly cool this chip needs to be rated 73°C 38°C / 103W = 0.34°C/W. This figure includes the resistance of both the thermal interface material (thermal grease) and the heatsink itself, so if you used a thermal grease with a known resistance of 0.01°C/W, the heatsink would need to be rated at 0.33°C/W or less. You can use another useful formula to describe processor power: Ppower = C x V2 x F Ppower is the maximum power output of the processor, C is the capacitance, V2 is the voltage squared, and F is the frequency. From this you can see that if you double the frequency of a processor, it will consume twice as much power, and if you double the voltage, the processor will consume four times as much power. Consequently, if you lower the voltage by half, it will consume only one fourth the power. These relationships are important to consider if you are overclocking your processor because a small increase in voltage will have a much more dramatic effect than a similar increase in speed. In general, increasing the speed of a processor by 5% increases the power consumption by only the same amount. Using the previous heatsink calculation, if the processor speed was increased by 5%, the 103W processor would now draw 108.15W, and the required heatsink rating would go from 0.34°C/W to 0.32°C/W, a proportional change. In most cases, unless you are overclocking to the extreme, the existing heatsink should work. As a compromise, you can try setting the voltage on manual and dropping it a small amount to compensate, thereby reducing the power consumption. Of course, when you drop the voltage, the CPU might become unstable, so you need to test this. As you can see, changing all these settings in the interest of overclocking can take a lot of time when you consider all the testing required to ensure that everything is working properly. You have to decide whether the rewards are worth the time and energy spent on setting it up and verifying the functionality. Note that most professional heatsink manufacturers publish their °C/W ratings, whereas many of the "boutique" heatsink vendors do not. In many cases, the manufacturers of many of the more extreme heatsinks don't do the testing that the professional manufacturers do and are more interested in the looks than the actual performance. Installing a HeatsinkTo have the best possible transfer of heat from the processor to the heatsink, most heatsink manufacturers specify some type of thermal interface material to be placed between the processor and the heatsink. This typically consists of a ceramic, alumina, or silver-based grease, but it can also be in the form of a special pad or even a type of double-stick tape. Some are called phase-change materials because they change viscosity (become thinner) above certain temperatures, enabling them to better flow into minute gaps between the chip and heatsink. In general, thermal greases offer higher performance than phase-change materials, but because they always have a lower viscosity, they flow more easily, can be messy to apply, and (if too much is used) can spill from the sides onto the socket and motherboard. Typical factory-supplied active heatsinks usually include a preapplied phase-change thermal material. However, if you choose to install your own heatsink, you must make sure you have thermal grease. It is usually supplied with the heatsink, or you can use third-party products. No matter what type you use, a thermal interface aid such as thermal grease or phase-change material can improve heatsink performance dramatically compared to installing the heatsink dry. Thermal interface materials are rated by thermal conductance (in which case higher is better) or thermal resistance (in which case lower is better). Unfortunately, several industry-standard rating scales are used to measure performance, often making product comparisons difficult. Some measure the thermal conductivity, and others measure the thermal resistance; and the scales used can vary greatly. The most commonly reported specification is thermal resistance in degrees Centigrade per watt (°C/W) for an interface layer 0.001 inch thick and 1 square inch in size. For a given material, the thinner the interface layer or the larger the area, the lower the resistance. In addition, due to other variables, such as surface roughness and pressure, it is often impossible to directly compare different materials, even if they appear to use the same ratings scale. As a means of offering some sort of comparison, let's look at the effect on processor temperatures by using thermal interface materials of different specifications. Currently, the highest-thermal-output processor is the Pentium 4 3.4E, which is rated at 103W thermal output, with a surface area on the heat spreader of 1.5 square inches. Table 2.15 shows the rise in temperature that will result from using thermal interface materials of different C/W specifications.

Most of the better thermal greases are rated from 0.005C/W to 0.02C/W per square inch, which would result in a rise of between 0.34°C and 1.37°C. Even if there were a "perfect" thermal grease available, it would reduce the CPU temperature by only less than 2°C over most of the products currently on the market. Actual tests have been done on multiple brands of thermal greases, and in most cases, the differences in temperature readings between different brands are insignificant. Most of the premium products on the market have very similar performance. You can purchase thermal grease in small, single-use tubes or larger versions that can service multiple processor installations. Most of the recommended thermal greases include alumina or silver, which offer the lowest thermal resistances. Silver is generally the best but is significantly more expensive, and its real-world differences are very slight. One brand (Arctic Silver) has even developed a following sufficient to cause others to counterfeit the product and name. The important thing to note is that, based on calculations as well as tests, there is only a couple degrees' difference in CPU temperature under full load when substituting one brand of thermal grease for another. If you want the best, you should choose a compound with embedded silver. The next best option is alumina, and the next best is the less expensive (and somewhat less effective) ceramic-based greases. Figure 2.35 shows the thermal interface pad or grease positioned between a processor and heatsink. Figure 2.35. Thermal interface material helps transfer heat from the processor die to the heatsink. |

EAN: 2147483647

Pages: 240