11.6 ISO 9001 Breakeven Point Methodology

11.2 ISO 9001 Benefit Methodology

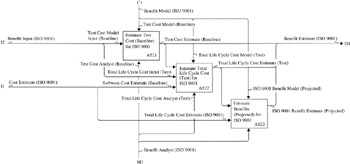

The benefit methodology for ISO 9001 is a procedure to measure, quantify, and analyze the amount of money returned. ISO 9001 results in higher productivity and quality, resulting in lower development and maintenance costs. Benefit is the economic value of using ISO 9001 to create a new and improved software process. Its benefit methodology is a three-part process that consists of estimating test costs, total life cycle costs of testing, and benefits. Its benefit methodology consists of a variety of defect models used in combination. Key elements include the test cost model and the total life cycle cost model. Some of the benefits are due to increased productivity, resulting in up to a 15% decrease in software development costs. Increased productivity is factored into the total life cycle cost model. The test and total life cycle cost models are used to compare the total life cycle costs of software testing to those of ISO 9001. Figure 55 illustrates the benefit methodology for ISO 9001.

Figure 55: Benefit Methodology for ISO 9001

Estimate test cost (baseline) for ISO 9001: The objective of this activity is to estimate the cost of removing the maximum number of software defects using software testing. The substeps include: estimate post-test defects (baseline) for ISO 9001 and estimate baseline test cost ( projected ) for ISO 9001.

Estimate total life cycle cost (test) for ISO 9001: The objective of this activity is to estimate software development and maintenance costs associated with using software testing. The substeps include: estimate total software cost (test) for ISO 9001, estimate total test cost (test) for ISO 9001, and subtract total test from software cost for ISO 9001.

Estimate benefits (projected) for ISO 9001: The objective of this activity is to compare software development and maintenance costs of testing and ISO 9001. This substep includes: subtract total life cycle cost of ISO 9001 from test for ISO 9001. It is assumed that rigorous testing was used prior to adaptation of ISO 9001. However, it is not assumed that peer reviews or the Software Inspection Process was used before, during, or after the deployment of ISO 9001.

EAN: 2147483647

Pages: 145