Section 30. Murphy s Analysis

30. Murphy's AnalysisOverviewMurphy's Analysis[52] is another useful change management tool for the early stages of a project. It is applied during the early section of the Define Phase. The Team at this point needs to determine what the Customer Requirements are for the process, the difficulty being that the Team does not know what they don't know. It is difficult to interview a Customer with absolutely no understanding of the problems the process faces; so before any interviews can take place, the Team has to do enough groundwork to determine what questions to ask and how to guide the interviewing. This is where a Murphy's Analysis performs a useful function.

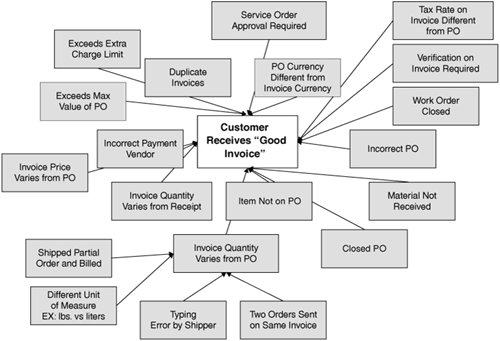

The Team use the Murphy's Analysis as a brainstorming tool to identify how the process can fail to function perfectly, as in Figure 7.30.1. Figure 7.30.1. An example of a Murphy's Analysis for an invoicing process. Based on the results of the Murphy's Analysis, the Team has a reasonable view of possible areas to investigate during the interviewing process. Note that the Murphy's Analysis result is not considered in any way to be the VOC; it is only one of a series of tools used to identify the VOC. A second useful function of Murphy's Analysis is that during the early stages of a project there is still venting that needs to be done by Team members. What better tool than one that focuses on the negatives in the process. LogisticsCreating a Murphy's Analysis is absolutely a Team activity and should not be done by the Belt in isolation. Also, the Belt should not be tempted to create a straw man of the Murphy's Analysis; rather, it should be created from scratch with the whole Team present. It generally takes the Team 4560 minutes to generate a reasonably useful result. The Team needs flipchart paper, wall space, sticky notes, and pens. RoadmapThe roadmap to creating the Murphy's Analysis is as follows:

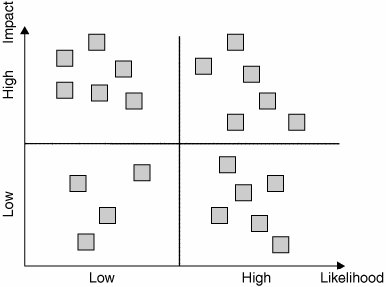

Interpreting the OutputAlthough Murphy's Analysis is a great tool prior to Failure Modes and Effects Analysis, its primary purpose as per the "Overview" section is to structure the Customer Interviewing process. The high impact and high likelihood failure modes should be key inputs to the questions used during the interviewing process, see "Customer Interviewing" in this chapter. |

EAN: 2147483647

Pages: 138