5.1 Transceivers

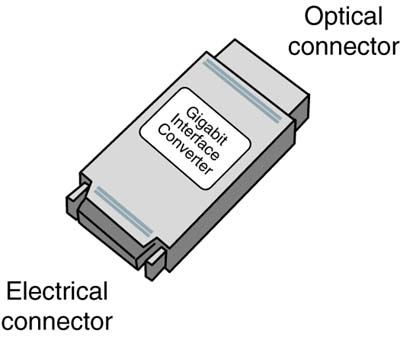

| Gigabit interface converters, or GBICs, are still commonly used for Fibre Channel applications. GBICs are removable media and so provide flexibility for configuring either optical or copper cabling. The selection of GBICs for SAN interconnection is as important as the selection of the proper switch or hub, because without signal integrity at the link level, no higher functions can be performed. GBICs are manufactured to a de facto standard form factor, and that enables use of various vendors' transceivers in the same device chassis. As shown in Figure 5-1, an optical GBIC provides an SC connector for multimode or single-mode fiber-optic cabling on one end, and the electrical connector to plug in to the device port on the other. Figure 5-1. Optical GBIC with standard SC connector

First-generation optical GBICs used edge-emitting CD lasers that is, laser components normally used in consumer CD products. For high-speed data transport, only the highest-quality CD lasers can be used. Wafer manufacturing techniques for CD lasers require separation of the discrete components for testing to ensure quality, and that contributes to manufacturing overhead and cost. In addition, compared with other kinds of lasers, CD lasers consume more power, radiate more heat, and are more susceptible to loss of calibration over time. These inherent problems of CD technology have encouraged the development of alternative laser products in particular, vertical cavity surface emitting lasers, or VCSELs. VCSEL technology has been in development for some time, awaiting resolution of obstacles to mass production. In the past few years, these problems have been solved one by one, allowing manufacture and packaging of second-generation laser products and, for Fibre Channel applications, manufacture of second-generation GBICs. Unlike edge-emitting CD lasers, vertical cavity lasers emit light perpendicular to the surface of the wafer substrate, as shown in Figure 5-2. VCSELs also consume less power, radiate less heat, and maintain calibration better than their CD cousins. And because VCSELs can be tested at the wafer, as opposed to the discrete component level, manufacturing and quality testing can be performed more efficiently. GBIC manufacturers have converted from CD lasers to VCSELs, and that helps to ensure that these physical-layer components will maintain calibration and therefore data integrity at the system level. Figure 5-2. Edge-emitting CD laser and vertical cavity laser components

Another advance in GBIC technology is the development of serial ID functionality. Originally an optional feature of the GBIC specification, serial ID has been engineered into second-generation products to provide a higher level of management at the physical layer. Serial ID allows a supporting enclosure such as a hub, switch, or HBA to query the GBIC for inventory or status information. Inventory information includes manufacturer, date of manufacture, serial number, speed, media and lengths supported, and other useful tracking information. Depending on the vendor, status information may include current power consumption, output, and diagnostic data. Serial ID relies on the supporting enclosure to solicit this information. This implies that the hub, switch, or HBA can query the GBIC and report its findings to a management application. GBICs were initially developed for 1Gbps transmission. Current products typically accommodate both 1Gbps and 2Gbps signaling and depend on the clock and data recovery circuitry on the device port to provide the appropriate clock rate. In addition, some GBIC manufacturers support both Fibre Channel 1.0625Gbps and Gigabit Ethernet 1.25Gbps signaling, enabling customers to use the same type of GBIC for different applications. Concurrent with the development of 2Gbps Fibre Channel, vendors have achieved higher port density in the same chassis footprint by substituting new small form factor transceivers in place of the traditional GBIC. Small form factor transceivers provide the same functionality as GBICs but in a more compact package. Small form factor transceivers may be fixed (permanently attached to the device port) or, as shown in Figure 5-3, pluggable. The pluggable variety is typically referred to as SFP (small form factor pluggable). Figure 5-3. Small form factor pluggable transceivers

Although handling the small form factor transceivers may be a bit awkward for administrators with large fingers and opposable thumbs, these devices enable very high port density for Fibre Channel switches and directors. It is also possible to mix small form factor transceivers and GBICs at each end of the cabling plant so that storage devices using GBICs can be attached to SAN switches using the more compact SFP connectors. |

EAN: 2147483647

Pages: 171