Developing a Kanban Design

Overview

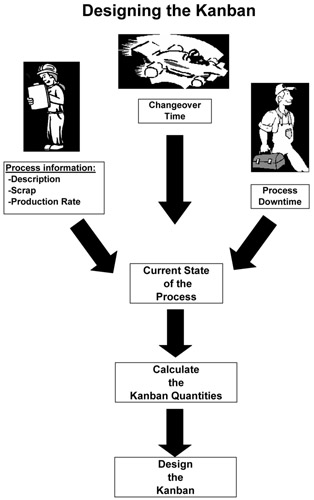

Many people think they only need to figure out the size of the kanban and they are ready to start up their kanban. Unfortunately, once they calculate the kanban size they are only partially ready. To successfully implement a kanban requires not only setting container quantities , but also the development of a design, deployment of the design, and training of the design. This chapter and the next two chapters will address these three topics. Thus our process flow expands, as shown in Figure 5-1, to include designing the kanban.

Figure 5-1: The Next Step in the Implementation of Kanban Scheduling: the Kanban Design.

When we think of kanban design we should think about three things:

- Selecting the signaling mechanism for the kanban

- Developing the rules for operation of the kanban

- Creating the visual management plans for the kanban

These three items will ensure that you have a design that can be successfully implemented. Consider each activity as an integral step on the road to successful implementation.

Setting up the scheduling signal means to develop a signal that tells the production operators when to:

- Produce parts

- Change over

- Stop production

This signal replaces the traditional production schedule. The signal can be cards, buggies, objects on a fixed board, etc. The only requirements for selecting a signal are that it must be unambiguous, readily understood , and maintainable .

The rules you develop for the kanban will drive its operation. They will be the guidance that allows the operators to control the production schedule. The rules should include directions on sequences, decision points, and anything else that will help production operators make the right decisions. Spell out who will perform what task, when to get help, who to go to for help, and what these "helpers" will do when contacted. The rules should use pictures and diagrams to facilitate understanding. Remember: if you want something to happen, then it better be in the rules.

Once you have developed a signal mechanism and the rules, you will need to determine how to communicate this information. The information should be communicated through your visual management plan. The visual management plans should include: putting up signs, marking or taping floors, posting the rules, posting job aids, etc. Your goal should be that anyone who walks into the production and material storage areas should immediately be able to determine the status of production, what needs to be produced next, and where to get parts. Additionally, your visual management plan should communicate all the other "everybody knows " stuff ” because everyone doesn't know.

Team Activity

Although you may have skated on involving the entire team in the previous steps, don't do it in the design phase. By creating a design as a team you will increase buy-in and are more likely to create a design that addresses all the issues.

The team will be able to identify the roadblocks to the success of the program. A successful design will answer the team's concerns and questions. When the design achieves this objective, then you're on your way to a successful kanban implementation.

Also, consider the kanban a work in progress. As you operate the kanban and gain more information, make changes that will:

- Improve its operation

- Integrate in new information

- Correct the loopholes that prevent flow

Don't be afraid to change kanban quantities when the calculated amounts do not let the preferred production sequence occur as planned.

Develop a Concept That Works for Your Organizational Culture

As you embark on the design, keep the culture of your organization in the back of your mind. Organizational culture will play a big role in implementation success. Consider the level of empowerment that exists in the production operation. Then consider past history. Use this information to develop a scheduling system that fits your culture. Do not select a signal just because you "saw it" somewhere else and it looked neat. Make sure you carefully consider how the production operators will manage the signal and their ability to make decisions based on the signals provided. Use these guidelines when selecting the scheduling signal:

- Keep the signals simple

- Make sure that each signal only directs one course of action

- Don't have duplicate signals

- Make the signals easy to manage

Kanban Cards

When most people think of kanban they automatically think of kanban cards, probably because the Toyota Production System relies heavily on the use of cards for their signals. But, be aware that many people have strong feelings about the use of cards as signals because of bad experiences with losing the cards or the cards being mismanaged.

What are these mystical items called kanban cards? They are essentially pieces of paper that travel with the production item and identify the part number and amount in the container. The cards can include other information, such as who to call for service or when to take the cards back to the production department. The cards are typically about the size of the old computer punch cards, but they can be any size that works for you. We also recommend that they be brightly colored so that they are easy to spot as they make their way through the process. Figures 5-2 and 5-3 show examples of two kanban cards.

|

Part Number: |

80800-14898 |

|

Part Name : |

10 V Power Supply |

|

Production Line: |

Line A |

|

Container Type: |

Plastic 12 14 |

|

Container Quantity: |

20 |

|

Storage Location: |

Portable Radio Line |

|

Production Operation: |

50 |

|

Bin Location: |

C-3 |

Figure 5-2: Kanban Card Used Between Processes in the Same Factory.

|

Part Number: |

80800-14898 |

|

Part Name: |

10 V Power Supply |

|

Supplier: |

Smith Electronics |

|

Vendor Number: |

133345 |

|

Container Type: |

Plastic 12 14 |

|

Container Quantity: |

20 |

|

Delivery Interval: |

Daily |

|

Storage Location: |

Portable Radio Line |

|

Production Operation: |

50 |

|

Bin Location: |

C-3 |

|

Delivery Location: |

Dock 5 |

Figure 5-3: Parts Ordering Kanban Card Used Between Supplier and Customer.

The kanban card serves as both a transaction and a communication device. Kanbans that use cards usually follow this simple routine:

- A card is placed with the completed production container (typically, in a protective sleeve of some sort ).

- The container with its kanban card is then moved into a staging area to wait for use.

- When the container is moved to a production work center for use, the kanban card is pulled from the container to signal consumption.

- The kanban card is then placed in a cardholder, or kanban post, to await transit back to the production line.

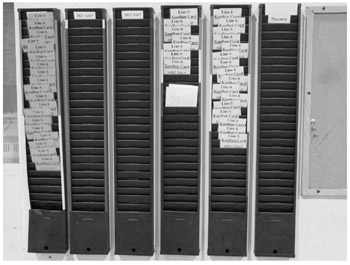

- When the kanban card returns to the production line, it is placed in a cardholder that has been set up to provide a visual signal for operation of the line. (Figure 5-4 is a picture of a cardholder rack.)

Figure 5-4: Kanban Cardholder Rack. - The kanban card sits in the cardholder waiting to be attached to a completed production container.

Although the cards are conceptually simple, many people have had varying levels of success with the cards. In their rush to emulate the system used by the Toyota Production System, many "would be" practitioners have applied a one-size-fits-all philosophy and ended up with failures or logistics problems when trying to manage the cards. The inappropriate use of the cards and the unjustified shrinking of their inventories drove many materials and production managers crazy trying to keep up. These horror stories also became the seeds of the opposition to kanban and a cornerstone of the MRP production scheduling craze.

So if cards are so bad, then how do you make them work? To be successful with kanban cards, you must make it easy for people to pull the cards. If you set up the kanban so that people have to back-track, then they will forget from time to time. The key to utilizing the cards is to put the card post in the path of the material's flow. Also, make sure the rules specify who picks up the cards and how often to ensure the cards make a round trip. For example, if the parts are staged at the production cell, then place the card post at the first operation in the cell .

When you make kanban cards convenient to use and specify the return loop, kanban cards work just fine.

Are There More Options Than Just Kanban Cards?

Luckily, the answer to the above question is a resounding yes. The kanban signal can be anything that makes sense to your production operation and conveys a clear replenishment signal. As with the kanban cards, always put the signal in the path of the material flow and have a plan for getting the scheduling signals back to the production operations. Some of the more common methods (and variations of these options) are discussed below to give you ideas for your own implementation:

- Look-see

- Kanban boards

- Two-card system

- Faxbans (or e- mails )

- Electronic kanban

- Warehouse racks

- Move/production kanban

These options and their variations are by no means the only options available. When looking at possible designs, open yourself and your team to all possibilities. Be creative ”invent new options of your own or springboard off of our suggestions to create your own variation. (By the way ”send us a picture and description of any new ones you create or any new variations of our suggestions. We also want to keep expanding our knowledge.)

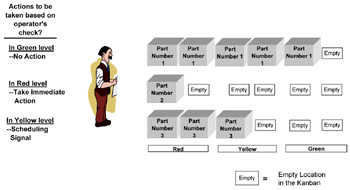

Look See

Whenever possible, your kanban signal should rely on the most reliable sensor ”your eyes. This form of kanban signal, called a "look-see," consists of visual signals such as floor markings or signs that tell you at a glance when to replenish the item. The basic rule with a look-see signal is that if you can see the yellow signal, then it's time to replenish the item. The red, or danger, signal is also integrated into this scheme. Look-see signals greatly aid in the implementation of the kanban supermarkets discussed in Appendix B. Figure 5-5 shows an example of a look-see scheduling signal.

Figure 5-5: Look-See Scheduling Signal.

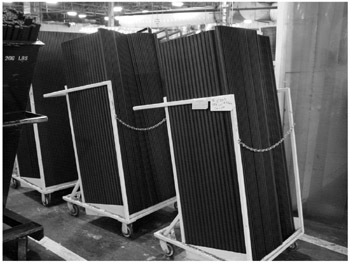

A special case of the look-see signal is the use of containers as the signal. The container is specifically marked to show the part number and the production quantity. When the container returns to the production process, it goes back into the queue. When you have accumulated a certain quantity of containers, this constitutes the yellow scheduling signal. The production operator will know what and how much to put into the container based on the information or standards set for the specific part number. Figure 5-6 shows a container used as a kanban signal.

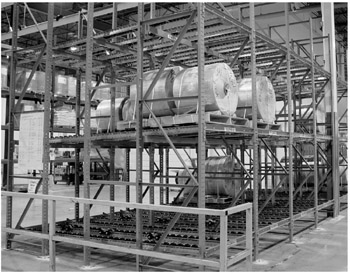

Figure 5-6: Container Used as a Kanban Signal.

Under very limited conditions, you can also set up a look-see kanban using warehouse racks. The racks can be painted or numbered to correspond to provide look-see signal. However, unless visibility can be maintained , this option can be tough to manage in a quick scan mode due to the typical size of racks. Forget this option if you are trying to cover several rows of racks or have conditions that hinder seeing the top rows. Instead, consider the card option discussed in the next section.

Another special case of the look-see signal is flow lanes. The flow lanes offer visual management of production material while managing stock rotation at the same time. Flow lanes are essentially aisles that the product travels down toward the production process. The product enters the flow lane from the back and moves forward in its lane. You will interpret the schedule signals just like any other look-see kanban.

The lanes, while very visual, can be hard to keep straight if you make them too long. This problem can be avoided by putting guides in the aisles (as shown in Figure 5-7) or using flow racks (as shown in Figure 5-8).

Figure 5-7: Flow Lanes with Guides to Control Movement of Containers.

Figure 5-8: Flow Racks Allow the Containers to Move Forward with Use of Gravity.

The guides are typically angle iron strips , sheet metal frames , or rails that have been attached to the floor. The guides allow the containers to move only in the specified direction.

The flow racks (or angled roller conveyors) use gravity to move the containers forward as the previous container is removed from the flow lane. The roller conveyor is readily available and can be found in most material handling or industrial sales catalogs. However, as the flow racks get longer and the containers get wider and heavier (such as pallet size), then the price tag for the flow racks can get very big.

If floor storage space is in short supply, flow racks can be purchased as stacked rows. This option will require you to answer a number of questions about container size and weight. Therefore, if stacked flow racks have appeal , contact a material handling specialist for assistance.

One other item to consider when setting up your flow lanes is to be sensitive to the number of rows from which product can be pulled. You may defeat the stock rotation benefit if you allow too many choices, as for example if the operators withdraw the containers closest to their operation, leaving the material staged further away to age. There is no stock answer for this, but use common sense and talk with your operators.

Kanban Boards

The kanban boards are a variation on the kanban cards. Instead of the cards, the board simply utilizes magnets, plastic chips, colored washers , etc. as the signal. The objects represent the items in inventory. However, instead of chasing cards around the building, you are moving the objects around on a board. The movement of the objects corresponds to the production and consumption of full containers of product. The process works like this:

- As a container of product is completed and moved into inventory, an object gets moved into the inventory section of the board.

- When the container is consumed or moved to a staging area for consumption, then an object gets moved into the awaiting production section of the board.

To determine what gets produced next, you look at the board and follow the rules.

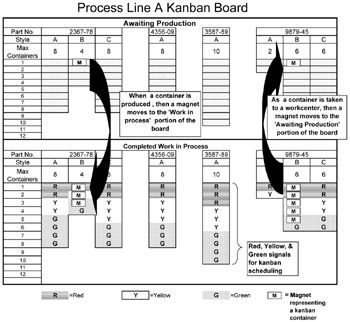

Figure 5-9 graphically shows an example of the movement of objects on a kanban board. Notice how only the bottom of the board contains the red, yellow, and green signals? This allows for only one scheduling signal ”even though the number of colored cells in the top and bottom sections is equal. Figure 5-10 shows a picture of a kanban board that uses magnetic pieces for scheduling signals.

Figure 5-9: Kanban Board Set-Up and Operation.

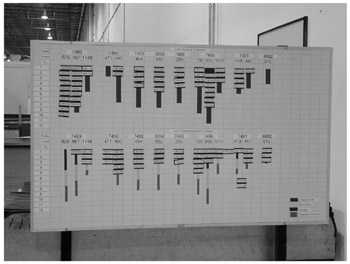

Figure 5-10: Kanban Using a Magnetic Board for Scheduling Signals.

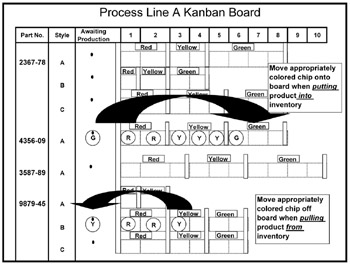

The pieces used to the show board status and product movement are not limited to magnets. In fact, kanban boards using chips, washers, etc. can actually simplify movements on the board. The simplification comes from collapsing the "awaiting production" area of the board, as shown in Figure 5-11.

Figure 5-11: Kanban Using Plastic Chips.

Kanban boards work best when two conditions exist in the relationship of inventory storage and the production process:

- The board can be positioned in the path of the flow of all the material to the customer (similar to the card system)

- The board can be positioned so that the production process can see it and follow the visual signals

If these conditions can be met, then the board works wonders. It is visual and provides an up-to-date schedule status. It also eliminates one of the major objections to the kanban cards ”people forget to return the cards to the card racks. The board also makes it easy to add and subtract containers. In fact, if these two conditions can be met, then we recommend boards as our first choice for a scheduling signal.

Two Card System

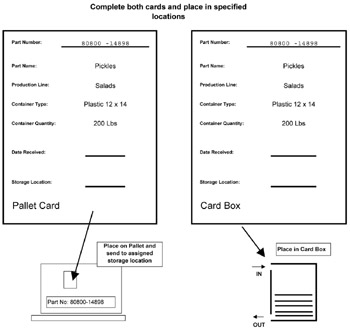

A two-card kanban system works well in situations where product rotation is also an issue. This system, which is a hybrid of the kanban board and the kanban card racks, uses two companion kanban cards to signal location and product age. It is typically used for large items where flow racks are not utilized. The two-card system works like this:

- When product is produced or received from a vendor, two cards are pulled from a kanban card rack and filled out:

- One kanban card goes with the container

- The second kanban card goes into a special first-in, first-out (FIFO) box.

- Whenever a container of this product is needed, a material handler goes to the FIFO box and pulls out the bottom card.

- The material handler then goes to the location written on the card and pulls this product for the production operation.

- The material handler then takes both cards and places them in the kanban card racks, which show the schedule signals for production or reorder.

This system, if maintained, allows pallet size items to flow while managing product rotation. It works especially well when used for floor stacked items. As you might suspect, detailed rules and training play a large part in the success of this kanban system. Figure 5-12 shows the FIFO box used for this kanban. Figure 5-13 shows an example of the cards used for a two-card kanban.

Figure 5-12: FIFO Box Used for the Two-Card Kanban System.

Figure 5-13: Example of the Cards Used for a Two-Card System.

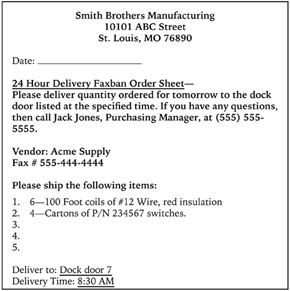

Faxbans (or E mails)

Faxbans (or their twenty-first-century cousin ”e-mail) are just a special variation of the kanban card system. They are used to order replenishment of products within large plants, from off-site ware- houses , or from vendors . This system works as follows :

- You set up a preset replenishment notification time with the recipient (for example, 12 PM each day).

- You then look at your requirements and fax or e-mail the order before the appointed time.

- The recipient then fills the order and delivers it at agreed-to time and intervals (for example, at 7 AM the next day for the previous day's 12 pm order).

The system is a means of communicating usage requirements over a predetermined interval. The delivery times are typically short ”under one week and, more than likely, under one day. The system helps cut down on the time wasted trying to manage purchasing organization bureaucracies, which allows for shorter lead times. The system requires preplanning and coordination. Because this system is faceless, make sure you plan on backup personnel to keep it going during absences and vacations .

The format of the fax sheet (or e-mail) should be agreed to by both parties. This sheet becomes the vehicle for communication and it should not be subject to interpretation. The typical sheet includes date, time, routing instructions, part numbers , and order quantity. These sheets should be preprinted or set up as a template on a word processor program to control uniformity and speed up the information transfer process. It is also helpful to include an area on the form for special information or instructions. Figure 5-14 shows an example of a typical faxban sheet.

Figure 5-14: Typical Faxban Sheet.

Electronic Kanban

Electronic kanban is a term many people use when trying to avoid kanban implementation. They try to pass off their MRP systems as a kanban system because they are keeping their inventory levels at four to five days. However, as previously stated, a kanban only exists when production is based on usage (or demand). Therefore, since forecast systems do not meet this requirement, MRP scheduling systems do not meet the requirements to be called a kanban.

With this differentiation out of the way, we can now discuss what an electronic kanban really is. A true electronic kanban is a high-tech version of the faxban. It automatically transmits requirements or allows suppliers to access the customer's inventory status and ship replacement material. These systems are not conceptually difficult, but implementation can be complex. The systems are typically developed by larger companies that want to simplify their ordering process. They tend to be one of a kind and are tailored to a single company and its applications. Participating suppliers must be able to log into the system to receive the data. Therefore, the implementing company must be ready to provide assistance to their vendors.

Warehouse Racks

Earlier in the chapter we discussed using racks as a look-see signal. At that point we said this was a limited option and to use racks only if the area in question was manageable.

However, racks are an effective storage method that should not be avoided as a candidate for implementing kanbans when paired with an effective control mechanism. Racks simply need to have a companion tracking system to allow easier visual management of the storage space.

Any of the previously mentioned systems will work with the rack storage. The kanban cards, kanban boards, two-card system, or electronic kanban will help maintain status of the production items kept in the storage racks. With special emphasis on layout of the scheduling system, product rotation can also be integrated into the kanban structure.

However, as your storage space grows, we especially recommend using some sort of electronic kanban to maintain inventory levels. The summation capability and review format allow for easier transmittal of replenishment orders while still allowing you to manage visually. Again, the uniqueness of these applications can sometimes lead to the need for outside programmers for implementation; for example, cost can be an issue!

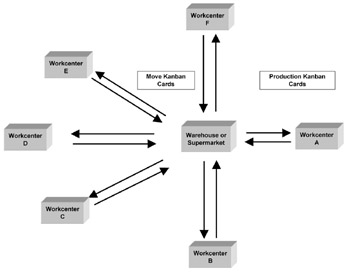

Move Production Kanban

The move/production kanban was first introduced by Toyota to handle kanbans between work centers. This kanban utilizes a production kanban to signal production and a move kanban to order material from storage. This kanban is very useful when one work center supplies common parts to numerous other work centers.

To explain the sequence, envision two work centers, A and B:

- Work center A supplies work center B.

- The parts from work center A are stored in a warehouse or supermarket until needed by work center B.

In a move/production kanban, when work center B needs another container of parts, it removes the move kanban card from the container and sends it to the warehouse. At the warehouse, a production kanban card is removed from the full container and replaced with the move kanban card from work center B. The production kanban card is then sent to work center A to authorize production of more parts. The full container with a move kanban is sent to work center B. Figure 5-15 shows this relationship.

Figure 5-15: Move/Production Kanban Steps.

Note that the system can be confusing and needlessly complicated when a work center supplies only one work center. However, when this work center supplies multiple work centers, it can be very useful. Figure 5-16 shows the relationship of one work center supplying multiple work centers.

Figure 5-16: Move/Production Kanban with One Work Center Supplying Multiple Work Centers.

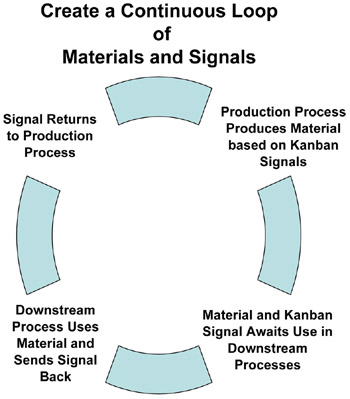

Determining Schedule Signal Logistics

Once you have selected the scheduling signal, you need to determine the signal and material logistics. You, and your team, need to determine how material and the kanban signal will move from the production process to downstream customers. You will also need to determine how the signal will make it back to the production process.

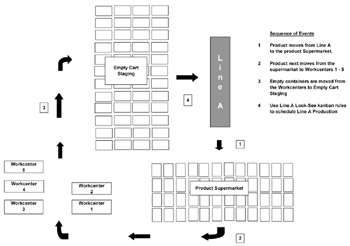

If you have not already done so then this is the perfect time to take a fieldtrip to the production process. During this fieldtrip, walk the path of the materials. Start at the production process and follow the same path the material takes to its customer. Look for stops, staging problems, and convenient ways to move the signals. Take this opportunity to determine the who, what, and when of the process. As Figure 5-17 shows, you must create a continuous loop of material and signals flowing from the production process to the customer and back again.

Figure 5-17: The Kanban Design Must Create a Continuous Flow of Materials and Signals.

One of the first logistic decisions will be how the material will be staged or whether you need to change how you currently stage your production material. Consider how the layout facilitates maintenance of the kanban cycle when making the staging decision. Also, do you want to keep the material in one spot or dispersed to the customer cells ? Consider how your organization manages material storage and stage the material where the highest kanban discipline will be maintained .

Consider the logistics of how the material moves into and out of the staging area. Look at the rotation issues and the ability to maintain order in the staging area.

When you have made the staging decision, make a drawing of the final layout. The drawing does not need to be fancy ”use a CAD drawing, MS Excel, or just a simple pencil drawing. The drawing helps to explain the flow and can serve as a training aid later. Figure 5-18 shows an example flow diagram drawn with MS Excel.

Figure 5-18: Kanban Flow Diagram.

As part of the design, you and your team will also need to decide where the scheduling signal will be located. When making this decision, remember the intent of the signal is to provide information for the production operators to make scheduling decisions. With this in mind, locate the scheduling signal as close to the operation as possible and in a very visible position. At the same time, position the scheduling signal so that you "pull" material through the production process instead of "pushing" it.

Make sure the signal location is also convenient to keep updated as production occurs. For kanban cards signal, locate the card post forward of the material storage area. This step will help in keeping the signal updated.

Develop Rules for the Kanban

Once the team has selected a kanban signal, it's time to develop the rules that govern its operation. The rule should address:

- The part numbers covered by the kanban

- How the design works ”how the cards, magnets, etc., move

- The meaning of the scheduling signals and how to interpret them

- Any scheduling rules of thumb (if required)

- The preferred production sequence (if one exists)

- Who to go to and what the "helpers" should do when contacted

- Any special quality or documentation requirements

Remember, you are drafting the rules to communicate how to run the kanban and to allow the process operators to schedule the line. The only way the production operators can take over scheduling the line is by the rules providing clear direction and scheduling guidance.

The rules should be specific and designed to make sense for your operation and the process. The rules should assign responsibilities by function (avoiding names ) and should not allow buck-passing of responsibility. Finally, never forget this basic thought when developing the kanban rules: If you want something to happen in a certain way, it better be spelled out in the kanban rules!

When you discuss how the pieces of the kanban will be manipulated, be specific:

- If this happens, then do this.

- The kanban card will be placed in _____ when ______ occurs.

- Move the magnet to the _____ when this occurs.

- When _____ happens, call ____ at ext. _____.

- Complete this form and fax to _____.

Once again, if you want the signals to move in a specific way, then you must tell everyone. Also, don't forget to tell everyone who, how, and when the scheduling signals (kanban cards, containers, faxbans) get back to the production process.

When you draft the scheduling rules make them easy and unambiguous to follow. Think through possible misconceptions and correct them so they will not occur. Spell out what signals a normal changeover. Spell out what signals an emergency changeover. Seek feedback to make sure that everyone else is as clear about how to interpret the signals as you and your team.

Additionally, the scheduling rules should contain clear-cut decision rules. The decision rules should help the production operators make consistent production scheduling decisions based on the stated priorities. The rules should provide rate information, if applicable , to allow the operator to develop production expectations. The decision rules should contain instructions on when and whom to call for help. Also, the rules should include all the "everyone knows this" items that everyone seems to forget from time to time. If you want the operators to schedule the line based on demand, then you have to give them the tools to do it.

If a preferred scheduling sequence exists, then list the preferred sequence in the rules. When developing a preferred sequence, specify the sequence in terms of normal operations. Potential items that can drive preferred sequences might include changing between paint colors, common raw materials, or common operational equipment. Whatever it might be, if you use these factors to schedule the line today, then include them in the rules by defining a preferred operating sequence. Also, make it clear that the schedule will deviate from the preferred sequence when red signals appear.

The rules should clearly state what the operators do when they get a red signal. The red signal is meant as a danger warning. Many people think red means hit the emergency stops and immediately change over. However, red means that a stock out will occur and action needs to be taken as soon as possible. Set the red levels at a point where you have time to react , not just to watch the kanban crash and burn.

Finally, use the kanban rules to develop a scheduling system that does not allow backsliding. Don't allow hidden forecast or MRP systems to really control the kanban. Make the production operators and the production managers use the scheduling signals to determine the schedule position and make decisions. Later, if you discover backsliding, figure out what is happening and make the necessary changes. Figure 5-19 shows a draft set of rules for the ten-part number example from Chapters 3 and 4.

- Empty containers will serve as the signals for Scheduling Line 1.

- Scheduling rules:

- Fill all the containers with the same profile before switching to the next profile unless a red signal occurs.

- Look at the control point for empty buggies to determine the next item to be produced. Select the next profile that has exposed the yellow blocks.

- If more than one profile is in the yellow zone (and no red signals exists), then run profiles (with containers in the yellow zone) in this sequence:

- 3502

- 3505

- 3508

- 3509

- 3511

- 3503

- 3504

- 3506

- 3507

- 3510

- If a red signal occurs, then notify a supervisor and begin making plans to change over to this profile.

- The supervisor should confirm this is a valid red signal before changing over.

- When no yellow (or run) signals exist, then notify the supervisor and prepare to shut down the line.

- Movement of containers. The attached drawing shows them flow of containers for this kanban. (Reference Figure 5-15)

- Line A technicians will move containers from Line A to the product storage area.

- Work center operators will return the empty containers to the empty container storage area.

- If you receive rejected material, then contact your supervisor immediately. All rejected material will be treated as consumed product until released from quality hold.

- If you have any questions regarding these rules, then see your supervisor or the materials scheduler.

Figure 5-19: Kanban Rules for the Ten-Part Number Example from Chapters 3 and 4.

Create a Visual Management Plan

Now that you have completed the design, it's time to design the visual management items for the kanban. The visual management plan will explain the kanban to everyone and visually instruct/ remind everyone how the kanban operates. The basic goal of your visual aids should be to answer the questions that pop up on a daily basis: Where do I get this from, where do I move that, which color buggy contains which part, is there a color scheme, do we have any-more of this part?

From experience, we know that you cannot overcommunicate with signs, colors, arrows, lines, etc. Essentially, think about the questions someone could have about the kanban, then develop visual answers to these questions. Also, consider when and where people will be when they have these questions, then place the answers in those locations.

Make your visual aids colorful and easy to read. Use these tips when developing visual aids:

- Keep the colors consistent with existing color schemes

- Avoid red ”typically associated with safety or quality

- Avoid yellow ”typically associated with safety

- Use large print for hanging signs and wall signs

- Avoid excessive words on your signs ”people don't read signs, they glance at them

Make forms and signs easy to update. To give homemade signs a professional look, use a word processing program to create the signs and hang them in Plexiglass holders, such as the one shown in Figure 5-20. Whenever you create signs or forms, don't forget to determine who will update them and under what circumstances.

Figure 5-20: Kanban Rules for the Ten-Part Number Example from Chapters 3 and 4.

Also, don't forget to consider ISO 9000 implications of the signs and forms. To make sure you don't run astray of these requirements, keep the people responsible for compliance in the loop. Work with them to achieve your desired outcome while still meeting their requirements.

If you plan to mark out your staging areas with lines, then consider using tape to mark the lines initially. Once you're happy with the layout of the staging areas, flow lanes , etc., paint permanent lines.

The same advice applies to floor markings . Initially, temporarily laminate paper signs and tape them on the floor. When you're certain that the signs are the ones you want and in the right location, make them into permanent signs.

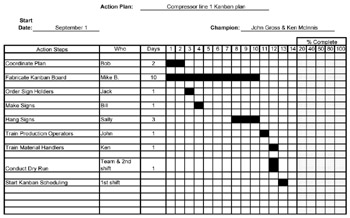

Develop an Implementation Schedule

Complete the design process by developing an implementation schedule. This schedule, which documents the steps required to transform your design into reality, must allow enough time to:

- Coordinate the final plan

- Purchase materials

- Install kanban signals and visual management

- Make the transformation from the current scheduling system to the kanban scheduling system

- Conduct training

The implementation plan is where the rubber hits the road. Assign members of your team to purchase the needed materials and to fabricate the necessary items to set up the kanban. Make sure that someone writes the required workorders, gets signs or boards hung, gets stands fabricated, and so forth, to support the schedule. Also, make sure to record all these plans so that you can track implementation progress.

Figures 5-21 and 5-22 show the same draft implementation schedule, but use different formats. These two formats illustrate a basic point: get decisions documented and don't get hung up on style.

Figure 5-21: Draft Implementation Schedule in Gantt Chart Format.

|

Action |

Who |

How Long (In Days) |

When |

|---|---|---|---|

|

Coordinate Plan |

Bob |

2 |

Sept 1 “2 |

|

Fabricate Kanban Board |

Mike |

10 |

Sept 1 “10 |

|

Order Sign Holders |

Jack |

1 |

Sept 3 |

|

Make Signs |

Bill |

1 |

Sept 4 |

|

Hang Signs |

Sally |

3 |

Sept 8 “10 |

|

Train Production Operators |

John |

1 |

Sept 11 |

|

Train Material Handlers |

Ken |

1 |

Sept 12 |

|

Conduct Dry Run |

Team's 2nd shift |

1 |

Sept 12 |

|

Start Kanban Scheduling |

1st shift |

Sept 13 |

Figure 5-22: Draft Implementation Schedule in Table Format.

Coordinate the Kanban Plan

Once you have an action plan, then you are ready to discuss coordination of the kanban design and how the production process will transition to kanban scheduling. When you consider the coordination process, consider who needs to approve, concur with, or understand the design. People who are probably interested in the plan include the plant manager, the materials manager, the production managers and supervisors, the material handlers, and (last but not least) all the production operators. Once you have determined who needs to buy into the plan, then determine how and what to communicate with them. Also, determine whether there is any specific order you want to followeach organization has its own coordination path , so follow yours.

As you proceed through the coordination process, be prepared for feedback that might change your plans. As a matter of fact, on the first two or three kanbans you implement, expect the rules to undergo several revisions as people begin the transformation to kanban scheduling. Address the feedbackuse what you can and discard the rest. As a courtesy , when you reject suggestions, always explain why you did not accept the suggestion. Finally, to help in implementation, plan the coordination process so the rules are finalized before the start of training.

Identify Who Needs Training

A subject closely related to the coordination process is training. As was true with coordination, you need to identify who needs training and what type of training. When making this list you should consider not only production operators, but also who will move the material and who will use the material. As a good rule of thumb for making this list, consider training everyone who touches the product. Figure 5-23 lists people to consider when making the training list. Also, note that not everyone needs to be trained to the same level and detail.

Figure 5-23: Who Needs Kanban Training?

The subject of training is so important that we have devoted Chapter 6 to the subject. For now, we'll just say that it's key to the successful implementation and is often overlooked.

Develop a Transition Plan

The last part of the implementation plan is to determine how you will physically transition to kanban scheduling. Some of the questions that you need to consider are:

- Will this be a running change?

- Will you need to build inventory to meet the kanban requirements?

- Will you need any special coverage to oversee the change such as sending the scheduler to third shift for the night the change occurs?

To answer these questions, use the team. By seeking their in-puts you not only develop a cross-functional answer, but you also plant the seeds of coordination and cooperation. Additionally, remember to consider the customer when you make this plan. You do not want to misstep and fail to support the customer (who doesn't care how you schedule).

Special Cases

As you begin to implement more and more kanbans, you will encounter constraints or unique situations ( manning , product mix, quantities , etc.) that complicate the implementation of kanban. When you encounter these situations:

- Look for commonality in the process

- Look for unique decisions rules

- Review your current informal scheduling rules for the process

- Look at the frequency of the various unique parts

Once you have looked at the problem from these angles, make a determination of whether you:

- Can implement a kanban

- Can implement a combination scheduling system

- Cannot implement a kanban

We have not defined combination scheduling in our previous discussions. Combination scheduling occurs when you place part of the process on kanban scheduling and manually schedule the special case parts.

When analyzing special cases, one method for clarifying the current scheduling rules is by making a decision flowchart that explains how you currently schedule the production process. The flowchart forces you to write down all those unspoken rules that you now use to control the production process. Once you have these rules written down, study them for ways to commonize or simplify the scheduling process to turn these rules into kanban operating rules.

Additionally, look at the production process for ways to consolidate or redistribute the parts to simplify the problem. Once you have simplified the problem, then you may find that the problem gets smaller or that it creates an opportunity to use the questions above to create a kanban design.

When you encounter special cases, don't be discouraged. Analyze the problem and apply the questions above. When you come up with a solution, make sure the kanban rules reflect these decisions. Also, after thoroughly analyzing the problem, don't be afraid to make the decision to not implement a kanban for this process (or these processes). The following sections look at some special cases and suggest ways to implement the kanbans.

Low Demand Mixed with High Demand

What do you do when the production process has several lower demand items? For example, the process has three parts that run monthly versus ten parts that run weekly? In this case, recognize the difference and set up the buffer inventory and kanban schedule quantity to produce the low volume parts at their current interval. Don't be concerned that these parts are out of sync with the other parts that run daily or weekly. By making these changes, you can allow the process to proceed in an orderly flow without having to implement a combination scheduling system.

Variable Manning Requirements

What if the production process has different manning requirements for different parts? First, look for the opportunity to consolidate parts with similar production manning requirements on the same line (lines) in order to eliminate the manning variance. Next, look at the possibility of implementing a combination scheduling system on those lines that still have variable manning requirements. Also, look at the possibility of prioritizing which parts on which lines get the available manpower, and establish a backup product on the line that does not get the extra manning.

More Than One Line Produces the Same Part

What do you do when a production process produces overflow parts for another production process that is over capacity? First, set a standard production quantity for the overflow parts on the secondary line. Next, create rules for the secondary line that requires the production operators to look at the primary line's kanban for its schedule position when making changeover decisions. These rules should instruct the secondary line to change over to the overflow part when the primary line is at a predetermined level.

Using the Workbook

Use the CD-ROM Workbook to help document the design. The design forms will serve as an outline to lead you through the design planning, rule formulation, and the visual management plans. The required training form will help to make a list of who needs to be trained. Additionally, action items forms and action plan forms will provide a format for assigning action items and documenting the coordination and transformation plans. (Training elements will be covered in Chapter 6 of the CD-ROM Workbook .)

Summary

Once you have determined the kanban quantities , the next step is design of the kanban scheduling signal. This chapter provides several design options for your consideration, adoption, or modification. Whatever signal you select or create, make sure it fits the culture of your organization.

When you have determined what type of scheduling signal you will utilize, then develop rules to control the operation of the kanban. The rules should include the following items:

- The part numbers covered by the kanban

- How the design workshow the cards, magnets, etc., move

- The meaning of the scheduling signals and how to interpret them

- Any scheduling rules of thumb (if required)

- The preferred production sequence (if one exists)

- Who to go to and what the "helpers" should do when contacted

- Any special quality or documentation requirements

Remember, you draft rules to communicate how to run the kanban and to allow the process operators to schedule the line. The only way the production operators can take over scheduling the line is by having rules that provide clear direction and scheduling guidance.

After you have the rules developed, develop a visual management plan to communicate how the kanban operates. Anticipate what questions are likely to arise from people operating and supporting the kanban and develop a visual management plan that answers their questions and guides them.

Finally, develop an implementation plan for deploying the kanban. The plan should address laying out the kanban, coordinating the design, training all participants , and the actual transformation from the current scheduling system to kanban scheduling.

Preface

- Introduction to Kanban

- Forming Your Kanban Team

- Conduct Data Collection

- Size the Kanban

- Developing a Kanban Design

- Training

- Initial Startup and Common Pitfalls

- Auditing the Kanban

- Improving the Kanban

- Conclusion

- Appendix A MRP vs. Kanban

- Appendix B Kanban Supermarkets

- Appendix C Two-Bin Kanban Systems

- Appendix D Organizational Changes Required for Kanban

- Appendix E EOQ vs. Kanban

- Appendix F Implementation in Large Plants

- Appendix G Intra-Cell Kanban

- Appendix H Case Study 1: Motor Plant Casting Kanban

- Appendix I Case Study 2: Rubber Extrusion Plant

- Appendix J Abbreviations and Acronyms

EAN: 2147483647

Pages: 142