Rack Specifications and Considerations

| Most large server rack deployments are custom built and installed by value-added resellers (VARs) who specialize in this technology. Even simple single-rack installations done for small workgroups require some forethought in terms of their specification. You need to know where to place the rack, what facilities are required, and how many related safety considerations are involved. Many issues surround the choices you make when you purchase racks and the equipment that fits into them. Some rack systems are very basic affairsessentially a set of posts or poles with regular holes where you bolt in your equipment. However, some rack systems come with fully developed ventilation systems, electronic monitoring equipment, a selection of walls and doors, and so forth. Your first constraint is likely to be the size of the rack. That size determines how much equipment your rack can support, but it is only one factor for you to consider. If you are populating a rack with equipment from a specific vendor, you will certainly want to consider that vendor's recommendations for the type of equipment. Racks are an important part of large OEM systems, and you can find a number of tools online to help specify and populate a rack system. The sections that follow describe some of the considerations involved. LocationThe first consideration when determining the proper location for a server rack or set of racks is the flooring. Will it be able to hold the static load, plus additional weight that constitutes your margin of safety? If you are installing the rack(s) into a room with a raised floor, you need to arrange the racks so that the flooring's own supports also lend stability to the rack. Part of your design calculation should be an estimation of the maximum weight of your rack. With that information in hand, it's useful to consult an architectural engineer to determine the carrying capacity of the room and the specific location where you plan to place your rack(s). That information may lead you to space your racks or may determine the maximum size of the rack you can use. You may also find that your site requires additional support or that some other change in your site is necessary. Unfortunately, there is no standard safety margin, and each building has its own weight tolerance. Assuming that a cabinet is approximately 3 feet by 4 feet, or 12 square feet, you need to leave at least a 3-foot clearance in the front and the back of the cabinet for convenient access and for heat dissipation. Server racks are constructed so that they don't require much space between them. However, if you have several racks lined up side-by-side, then every few racks, there should be enough room for an administrator or a support technician to access the back of the cabinet. When you populate a rack, one of the calculations you should make is the amount of heat the rack will produce. It's best to determine the maximum amount of heat that could be generated and then build the appropriate level of cooling into your location. Part of the specification of each component that you put into the rack should be its heat dissipation. For any component that doesn't specify the amount of heat that is given off, you can assume that the power rating of the power supply included in the equipment represents an upper limit for the heat that can be generated. That is, if your equipment is powered by a 500-watt power supply, then the power rating should be the upper limit of the heat that must be accommodated. If you don't know exactly how your rack is going to be populated, or if the rack is only partially populated when it is deployed, you need to make an assessment without having all the information you need to calculate the amount of heat that must be cooled. Consider the types of equipment that are to be used in your server racks, determine which unit uses the most power, and then multiply that power by the number of units that can be deployed in a server rack. Then you can use that number as your working estimate for the amount of heat you need to accommodate. When you are estimating heat dissipation, you need to be sure to include the equipment in your server room that supports each rack system. Equipment such as UPCs, lighting, and other external devices contributes to your heat assessment. Most companies with large server rack deployments install their racks in aisles or rows. With rows that are laid out perpendicularly, with cooling intakes on one side of the aisle and air returns on the other, you get the maximum amount of airflow. Server racks are most often cooled internally front to back, and then from bottom to top at the rear of the cabinet. When hot air rises, the cooler airflow into the bottom of the rack forces the hot air out of the exhaust at the top of the rack and into the room. To better facilitate airflow, it is recommended that you place your air-conditioning so that the airflow alternates in one direction down an aisle and in the opposite direction down adjacent aisles. SafetyLarge server racks have a number of features that can be safety issues. Some of these we've already touched on, while others will be discussed in more detail in the sections to follow. The following checklist is a short list of safety concerns you should keep in mind when implementing a server rack:

Large server racks can be quite heavy. Prior to designing and setting up a server rack, it's important to determine the static load of your flooring. If your flooring is the building's flooring, then the static load of the floor may be part of the design specification. At any rate, you should consult with a design architect or, better yet, a qualified structural engineer to obtain this information prior to making any commitments to purchase equipment. If you are installing a server rack(s) onto a raised data center floor, you need to check the static load capacities of both the raised floor and the building. If your server racks are deployed in an earthquake zone, you need to take special precautions when you set them up. Server racks should not be set up in an earthquake zone on standard raised flooring. Special flooring with honeycombs instead of simple framing should be used. It may also be prudent to support server racks with bracketing that allows the rack to shake or sway but limits the rack's motion in such a way that it can't tip over. Server racks contain some very power-hungry devices. Many servers, but not all, are left running on a 24x7 basis. Some people turn their server racks off overnight or during the weekend. When you power up a server rack, there can be a considerable power surge on your electrical system. It's a good idea to put a power sequence on your server rack to minimize the effect. Using a power sequencerwhich fires up one outlet at a time, waiting a second or two between powering up one outlet and proceeding to the next oneis a good way of avoiding power surges that can knock out systems in your server room. While on the subject of power, one consideration you need to address when specifying the components of a rack system is how you handle power outages or brownouts. In some ways, a brownout can actually be worse than a power outage because during a brownout, system components are still working, but with reduced power and at additional stress. Your server is more likely to have a component fail under those conditions. The best way to deal with power outages and brownouts is to install a UPS system for your servers and equipment, as covered in Chapter 14, "Power Protection." As mentioned earlier, EMI and RFI emissions are another issue that you should consider when designing your deployment. All computers sold in the United States must be certified as emitting radiation below a certain level. That level is such that it should be possible to get AM/FM or cell phone reception from a distance that is not too far away from the server itself. The U.S. Federal Communications Commission (FCC), as specified in its Part 15 Rules, defines A and B classes for all commercially operated electronic equipment. Class A is designated as what is acceptable in an industrial or commercial environment, and Class B is the acceptable standard for home or residential operation. Be aware that not all electronic components that you might want to use in your server rack will be properly certified. Although server racks are designed to create a Faraday cage effect and keep most, if not all, EMI and RFI emissions from escaping the cabinet, the interference of one component with another may be a feature that you might want to minimize. Any devices known to radiate EMI or RFI are best kept out of a server cabinet and housed in their own separate and shielded containers. Many companies build server racks or cabinets with special environmental controls to enhance and improve their safety. EMC Symmetrix storage servers ship with a number of sensors that can detect temperature, vibration, and other factors. A simple modem can call back to EMC's control room when there is a problem. During an earthquake in Japan in the late 1990s, several EMC Symmetrix systems detected the vibrations of the impending earthquake before it occurred. In other instances, temperature sensors have detected server room fires before the companies where the storage servers are deployed were even aware of them. Designing a Rack SystemIf you plan on setting up a server rack system, it's a good idea to design which components fit into the rack and where. A server rack can contain tens of thousands of dollars of equipment, and you want to make full use of your investment. Having a design also allows you to consider issues such as heat flow, where the rack's center of gravity is located, what cable runs you are going to need, and where to place not only hot running components but the fans and other systems needed to cool them. Visio DesignsThere are many places you can go to create designs for server racks. The one program that often gets discussed in this context is Microsoft's Visio, a drawing/entry CAD program that is now part of Microsoft Office. Visio has components in the PC & Peripherals, General Manufacturer Equipment, and Network Devices stencils that are designed to illustrate a standard rack environment. Several websites also provide libraries of Visio shapes that you can use to lay out a rack design. An example of this approach can be found at http://techrepublic.com.com/5100-6265-1039784.html, where Rick Vanover has provided a set of downloadable stencils you can use to design a standard rack design. The set includes the following:

Another source of Visio stencils can be found at Remtech (www.remtech.uk.com/shapes.html). Remtech's stencils let you design a rack in metric scale, with shapes such as shelves, cable trays, and rack-mounted systems, all of which are smart Visio shapes that snap into position on the rack. You should also visit the Visio Café and check out Bruce Pullig's stencils of Sun and EMC servers and other related equipment (www.visiocafe.com/brucepullig.htm). The Visio Café also lists other stencils you might want to explore. After you design your racks, you might want to use your designs to lay out the server room in which you place the racks. Visio has a set of room layout shapes that are in the Solutions>Business Diagrams>Office layouts. You'll want to lay out the room in an overview or plan view. After you've created the room's scaled shape, you need to populate the room with doors, electrical power rails, HVAC, and any other features of the room that will affect where you can place your server racks. Server Vendor Rack Design ToolsBeyond the generic approach of documenting the design of a rack deployment, you will find that many server vendors offer online tools that allow you to create racks containing their specific products. Dell, Hewlett-Packard, and IBM all have online tools of this type. They can be found at the following locations:

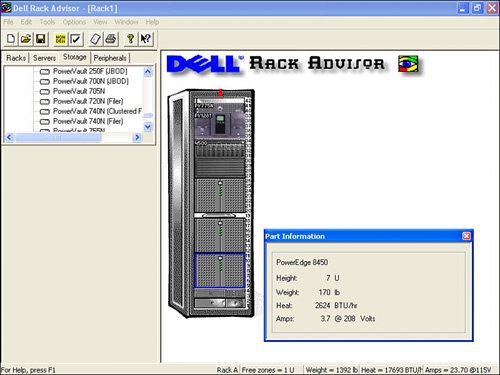

Figure 16.7 shows an example of a rack built using the Dell Rack Advisor, which is an online tool that lets you use a Dell rack or another standard rack design and populate it with Dell servers, storage components, and other parts. Figure 16.7. The Dell Rack Advisor lets you build server racks from Dell components and from its partners. It offers a limited facility to add non-Dell parts to your design. By using Rack Advisor, you can select the rack model you want (Figure 16.7 shows a 42U rack from Dell) and then populate the rack with components. The rack shown in Figure 16.7 has three 6U Dell servers, an array, a tape library, and a keyboard, among other things. Components are shapes that you drag and drop from the shape library. When a shape doesn't fit in the rack, the tool posts a message to that effect. When you try to add a component that has requirements that the rack can't support, such as a large UPS system, the tool posts a notice to that effect and doesn't let you add the component. When you have a valid design, you can save it or print it, as needed. |

EAN: 2147483647

Pages: 240

- Article 210 Branch Circuits

- Article 285 Transient Voltage Surge Suppressors (TVSSs)

- Article 390 Underfloor Raceways

- Example No. D2(a) Optional Calculation for One-Family Dwelling Heating Larger than Air Conditioning [See Section 220.82]

- Example No. D10 Feeder Ampacity Determination for Adjustable-Speed Drive Control [See 215.2, 430.24, 620.13, 620.14, 620.61, Tables 430.22(E), and 620.14]