| Traditionally, quality initiatives have been viewed as adversarial to cost-reduction objectives. Even today, goal-directed managers continue to consider quality-related expenditures a cost rather than an investment, despite the crusades of Deming, Taguchi, and Crosby. The idea that improved quality can improve cost-effectiveness is not totally new, but it has been gaining ground only in recent years. Growing acceptance of quality as an investment can be attributed to several factors: The success of Six Sigma, DFSS, and other initiatives: Several U.S. corporations, such as GE, Motorola, Allied Signal, and a score of companies worldwide, have deployed Six Sigma and Design for Six Sigma (DFSS) successfully and have delivered remarkable results in product and service quality while realizing enormous savings and other benefits.[1] (Table 4.1 compares Six Sigma/DFSS deployments at GE, DuPont, and Caterpillar with the Toyota Production System [TPS].) These initiatives have been the focus of much corporate, academic, and media attention in recent years, leading to greater awareness of quality as an essential component of business strategy. Table 4.1. Examples of Corporate-Wide Quality Deployments: Lean, Six Sigma, DFSS, and TPSCompany | Initiatives and Scope | Results |

|---|

GE | Six Sigma, DFSS, and Lean Six Sigma 10,000 black belts and 100,000 green belts in 2000 Expects to train up to 30,000 black belts 50,000 projects in 2002 Six Sigma assistance to customers in 2003 All new products to be developed using DFSS Initiated Lean Six Sigma in 2004 Six Sigma consulting service to suppliers worldwide Innovative across-the-board applications | $6.6 billion in savings in five years During the years 20022004, GE Transportation improved inventory turns from seven to nine, and GE Advanced Materials improved accounts receivables by six turns $2.7 billion in improvements in working capital in 20032004 Expects to save $7 to $10 billion annually in the long term $1.5 million in annual savings per black belt $1.0 addition to EPS Improvement in operating profit margins from 13.6% in 1995 to 16.7% in the third quarter of 1999 Huge reduction in the need for capital investments due to improved plant utilization | DuPont | Six Sigma and DFSS 250 master black belts 1,200 black belts 10,000 green belts One of every four employees participates in a Six Sigma project Completed 11,000 projects 4,000 projects with increased safety and reduced environmental impact Over 12,000 projects underway around the world in all regions and lines of business | More than $1.6 billion in cost savings in four years 50% of projects focus on cost reduction, 25% on transactions, and 25% on revenues, including top-line customer-related More than 1,000 top-line growth (TLG) projects were active in 2002 More than 500 financial analysts and managers have been trained in the specifics of Six Sigma financial metrics and reporting | Caterpillar | Lean Six Sigma and DFSS Leveraged across the value chain as a broad cultural philosophy to drive continuous process improvement, promote teamwork, process information, solve problems, and manage business First company to launch Six Sigma at all business units simultaneously10 manufacturing facilities in 24 countries worldwide concurrently 2,000 black belts, 14,000 green belts, 2,000 sponsors More than 25,000 employees and 15,000 projects in 2003 97 dealers and 240 suppliers | $138 million quarterly bottom-line improvement directly attributed to Six Sigma $1.6 billion cost reduction target $30 billion revenue target for 2010 from 2003 revenue of $20 billion Objective of 35% reduction in warranty-related costs | Toyota | Toyota Production System (TPS) aims to eliminate all kids of waste and improve productivity and quality. It's a way of life in Toyota and uses a number of quality systems and tools: Kanban (Just In Time) Jidoka (quality in the process) Small-lot delivery Deming's Plan, Do, Check, Act (PDCA) cycle and kaizen (continuous improvement) Heijunka (leveling of demand) Visual control 5S, or clean, orderly workplaces | Quality consistently ranks among the world's best More profitable than GM, Ford, DaimlerChrysler, and Volkswagen combined Lexus is the top luxury brand in the United States Lexus dealerships are the second most profitable Camry is the best-selling car The Toyota brand sells more than the Ford and Chevrolet brands Toyota, Lexus, and Scion outsell Chrysler, Dodge, and Jeep Surpassed Ford as the world's No. 2 automaker 11.7% of the world auto market in 2003 (10% in 2001 and has a goal of 15 % by 2010equal to that of GM) |

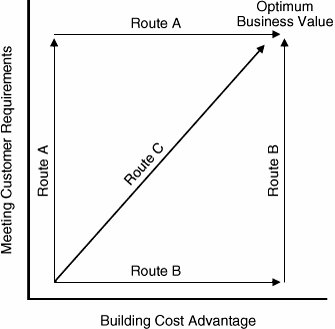

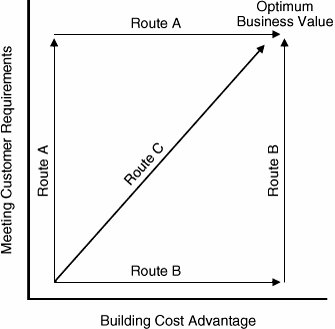

The Japanese miracle: We have witnessed the emergence of Japan as a major industrial power following the devastation of World War II. It is better understood now how Japanese corporations such as Toyota, Honda, and Sony have deployed Total Quality Management (TQM), Lean Production, and Taguchi Methods to gain quality and cost advantages. Congruence with the CEO's concerns: Management practices in the West have gradually adopted TQM and Lean Production systems. For example, Six Sigma, a variant of TQM, places much more emphasis on the bottom line and measurable short-term results on a project-by-project basis than the traditional TQM that has been practiced in Japan. A major factor in Six Sigma's attractiveness in the West is its record of delivering short- as well as long-term bottom-line improvements. The CEOs in the West can hardly ignore the stock market's short-term expectations. Jack Welch describes this challenge succinctly: "The only reason anyone has the title of manager is to manage short and long. ... Anybody can manage short. All you do is go in and for two years squeeze everything and look like a hero. Anybody can also manage for the long term, go in and say I'm going to deliver in 1995 and don't bother me until then. The hard game is balancing it."[2] Customer expectations: Customers in any industry can hardly be satisfied with offerings based on cost or quality alone. They ask for both. This doesn't mean that the product has to be all things to all people; it implies understanding the customer's cost and quality requirements and responding intelligently to those requirements. Competitive advantage: Even though a quality product can command a premium price, a cost advantage provides competitive cover, better margin, or both. In software development, the right strategy is to design software such that it optimizes both the customer's trustworthiness requirements (quality) and the software developer's cost requirements (Route C in Figure 4.1). For example, DFTS provides a systematic methodology to optimize various requirements at the lowest cost. In the absence of such a development model, software developers try to fulfill customer requirements first and then attempt to lower development costs (Route A) or, worse still, develop at a low cost first and then seek to meet customer requirements (Route B). Both these approaches are difficult to pursue and fail to deliver trustworthy software at the lowest cost. So here is the amazing revelation: Find a way to deliver as per the customer requirements, or it will cost you more! Figure 4.1. Alternative Routes to Creating Optimum Business Value

|