Why QFD?

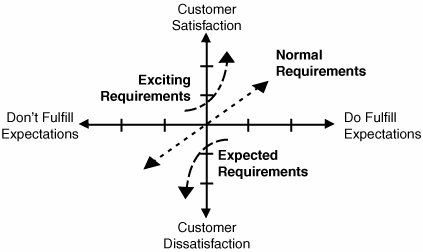

| QFD is a unique system for developing new products which aims to ensure that the initial quality of the product or service will satisfy the customer. In today's turbo economy, traditional design methods that rely on extensive concept and market testing and multiple rollouts take too much time and increase risk that copycat products will enter the market first. Best efforts driven by internal requirements risk failure to recognize important customer needs. QFD tools and methods can reduce these risks with a robust, traceable, and structured system of planning. Further, you can customize QFD to a specific project, whether it is software, a product, a service, or as in this case, a combination of all three. QFD is the only comprehensive quality system aimed specifically at satisfying the customer and, as in this case, the customer's customer (the theme park visitor). It concentrates on maximizing customer satisfaction (positive quality) and eliminating dissatisfaction (negative quality). QFD differs from traditional quality methods that focus on zero defects; after all, when nothing is wrong it does not mean that anything is right. QFD focuses on delivering positive value by seeking out both spoken and unspoken needs, translating them into actions and designs, and communicating them throughout each organization on the value chain to the end customer (the theme park visitor). Further, QFD allows customers to prioritize their requirements and benchmark us against our competitors. Then QFD directs us to optimize those aspects of our products and services that will deliver the greatest competitive advantage. No business can afford to waste constrained financial, time, and human resources on things customers don't value or where they are already the clear leader. History of QFDQFD began 30 years ago in Japan as a quality system focused on delivering products and services that satisfy customers. To efficiently deliver value to customers, it is necessary to listen to the "voice of the customer" throughout the product or service development process. The late Dr. Shigeru Mizuno, Dr. Yoji Akao, and other quality experts in Japan developed the tools and techniques of QFD and organized them into a comprehensive system to ensure quality and customer satisfaction in new products and services [Mizuno and Akao 1994, Akao 1990]. In 1983, a number of leading North American firms discovered this powerful approach and have been using it with cross-functional teams and concurrent engineering to improve their products, as well as the design and development process itself [Akao 1983, King 1987]. Service organizations have also found QFD to be helpful. One of the authors of this chapter, Mazur, used QFD in 1985 to develop his Japanese translation business, Japan Business Consultants, and saw revenues increase 285 percent the first year, 150 percent the second year, and 215 percent the third year [Mazur 1993]. QFD was an important part of Florida Power & Light's successful bid to become the first non-Japanese Deming Prize recipient in 1990 [Webb 1990] and in the 1994 Deming Prize awarded to AT&T Power Systems. Leading institutions such as The University of Michigan Medical Center [Gaucher and Coffey 1993, Ehrlich 1994], Baptist Health System [Gibson 1994, 1995], and others have applied QFD successfully in healthcare since 1991. Interesting service applications also include the development of an engineering Total Quality Management (TQM) curriculum at The University of Michigan College of Engineering [Mazur 1996a] and the application to employee satisfaction and quality of work life at AGT Telus [Harries et al. 1995], as well as in small and medium-size enterprises [Mazur 1994]. Integrating service and product QFD was a hallmark of the study Host Marriott completed to improve its breakfast service at U.S. airports [Lampa and Mazur 1996, Mazur 1996b]. Organizations have heralded QFD for such benefits as promoting cross-functional teams, improving internal communications between departments, and translating customer requirements into the language of the organization. Understanding customer requirements appears to be one of the weakest links in product and service design. In a survey of 203 projects at 123 industrial companies, managers rated 13 typical new-product development process activities in terms of what percentage of projects actually did the activity, and on a ten-point scale, how well they performed the activity. Least performed (25.4 percent of the projects) was a detailed market study of customer requirements, and when it was done, the quality of work was graded a 5.74 out of 10 [Cooper 1993]. Many product developers explain this by saying that customer requirements are often too vague, are never mentioned, change during the project, and even when met, are frequently not what customers want to buy. In QFD, you can employ several tools to clarify vague requirements, discover hidden ones, and prevent changes or misunderstandings by correctly analyzing their root benefits [Mazur 1997, Rings et al. 1998]. Prompting the development of these tools was a study done in Japan in 1984 that demonstrated that different types of requirements needed different approaches to understand [Kano et al. 1984]. Kano's RequirementsYou must consider three types of customer requirements to understand how meeting or exceeding customer expectations affects satisfaction (see Figure 25.1). Figure 25.1. Kano's Model of Customer Requirements

Kano's model is also dynamic in that what excites us today is expected tomorrow. That is, once introduced, the exciting feature will soon be imitated by the competition and customers will come to expect it from everybody. An example is the ability to have pizza delivered in 30 minutes. On the other hand, expected requirements can become exciting after a real or potential failure. An example might be when passengers applaud after a pilot safely lands an airplane in rough and stormy weather. The Kano model has an additional dimension regarding which customer segments the target market includes. For example, the caviar and champagne that are exciting on the domestic flight might be expected on the Concorde from New York to London. Knowing which customer segments you serve is critical to understanding your customers' requirements. Thus, eliminating problems handles expected requirements. You can gain little satisfaction or competitive advantage when nothing goes wrong. Conversely, you can gain great value by discovering and delivering on exciting requirements ahead of the competition. QFD helps ensure that expected requirements don't fall through the cracks and points out opportunities to build in excitement. In summary, Kano found that the exciting needs, which are most tied to adding value, are invisible to both the customer and the provider. Further, they change over time, technology, market segment, and so on. The QFD team understands these requirements best when going to the gemba (where the customer interfaces with the service) to observe, listen, and record the problems customers experience and the opportunities they wish to seize. Going to the gemba can be difficult for those who are used to seeing things from an internal point of view. They tend to see more process problems and solutions than customer needs. QFD tools help the team see the world from the customer's point of view. |

EAN: 2147483647

Pages: 394