Tool 89: Gozinto Chart

| AKA | N/A |

| Classification | Planning/Presenting (PP) |

Tool description

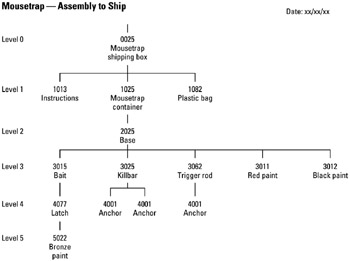

The Gozinto chart is a vertical tree diagram that displays hierarchical levels of detail of a complete product assembly to ship process. Developed by A. Vazsonyi, this project planning tool is of great value for kitting, bill of materials (BOM) auditing, parts/number identification, and operator training.

Typical application

-

To breakdown a product into its parts.

-

To flow out the assembly process.

-

To cross-reference parts data with the hierarchical levels of assembly.

Problem-solving phase

| → | Select and define problem or opportunity |

| → | Identify and analyze causes or potential change |

| Develop and plan possible solutions or change | |

| Implement and evaluate solution or change | |

| Measure and report solution or change results | |

| Recognize and reward team efforts |

Typically used by

| Research/statistics | |

| Creativity/innovation | |

| Engineering | |

| 1 | Project management |

| 3 | Manufacturing |

| Marketing/sales | |

| 4 | Administration/documentation |

| Servicing/support | |

| Customer/quality metrics | |

| 2 | Change management |

before

-

Tree diagram

-

Work breakdown structure (WBS)

-

Information Needs Analysis

-

Process analysis

-

Work flow analysis (WFA)

after

-

Failure Mode and Effect Analysis

-

Task Analysis

-

Potential Problem Analysis

-

Dendrogram

-

Activity analysis

Notes and key points

-

Gozinto chart numbering is by levels and BOM or part identification number. Example: 3015: 3 for level 3, 015 for bill of material or part ID number.

-

This is a similar approach to the work breakdown structure (WBS) chart.

Step-by-step procedure

-

STEP 1 List all parts required to completely assemble the product.

-

STEP 2 Draw a hierarchy of assembly, showing levels of detail from the top down to the basic level of parts.

-

STEP 3 Provide identification of parts; name and number each part charted.

-

STEP 4 Check completeness of chart and date.

Example of tool application

EAN: 2147483647

Pages: 326