Tool 44: Cost of Quality

| AKA | Cost of Quality Analysis |

| Classification | Analyzing/Trending (AT) |

Tool description

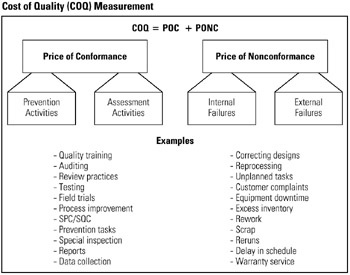

The cost of quality technique can be used as a powerful tool to identify and break down the readily apparent and the more hidden costs of quality activities. Costs are associated with conformance (prevention and assessment activities) and nonconformance (internal and external failures) factors.

Typical application

-

To identify total quality costs of operations.

-

To anlayze quality costs for the purpose of discovering cost savings and process improvement opportunities.

-

To educate the work force on the cost of quality or lack of quality.

Problem-solving phase

| Select and define problem or opportunity | |

| → | Identify and analyze causes or potential change |

| → | Develop and plan possible solutions or change |

| Implement and evaluate solution or change | |

| Measure and report solution or change results | |

| Recognize and reward team efforts |

Typically used by

| Research/statistics | |

| Creativity/innovation | |

| 1 | Engineering |

| Project management | |

| 2 | Manufacturing |

| Marketing/sales | |

| Administration/documentation | |

| Servicing/support | |

| 3 | Customer/quality metrics |

| 4 | Change management |

before

-

Data Collection Strategy

-

Activity Cost Matrix

-

Interview Technique

-

Focus Group

-

Starbursting

after

-

Cost-Benefit Analysis

-

Balance Sheet

-

Presentation

-

Process Analysis

-

Run-It-By

Notes and key points

Estimating Cost of Quality (COQ):

![]()

Step-by-step procedure

-

STEP 1 A facilitator team brainstorms and lists all quality factors for the purpose of estimating total operational cost.

-

STEP 2 Team participants receive assignments to collect actual cost data wherever possible. Other costs for quality-related activities need to be estimated by the process owners or department managers.

-

STEP 3 The facilitator sorts costs into conformance and nonconformance. See example Cost of Quality (COQ) Measurement.

-

STEP 4 The team searches the cost data for the major cost items and discusses alternatives to lower these costs.

-

STEP 5 A list of potential cost-saving action items is drawn up. This could also be a list of potential process improvements to greatly reduce or eliminate quality-related costs.

-

STEP 6 Participants use the checklist in this example to generate other ideas for further consideration and analysis.

Example of tool application

Cost of Quality (COQ) Measurement

EAN: 2147483647

Pages: 326