Section 3.13. How does a cultural transformation happen in the real world? What can SupplyOn tell us about how to manage the change inherent in ESA?

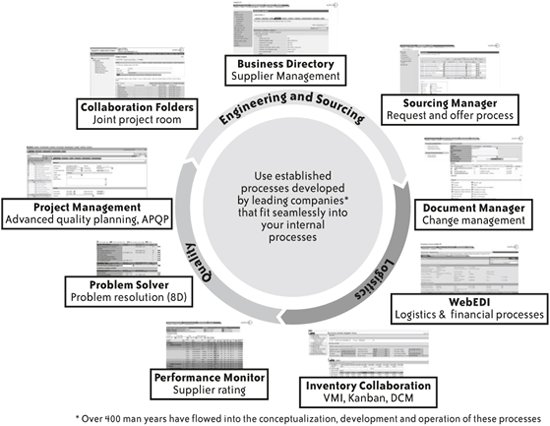

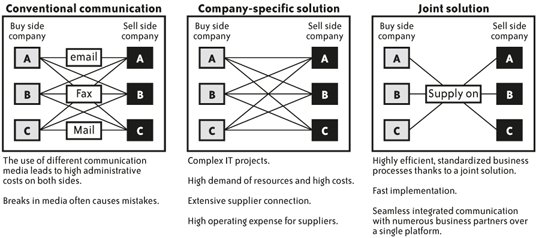

3.13. How does a cultural transformation happen in the real world? What can SupplyOn tell us about how to manage the change inherent in ESA?SupplyOn, based in Munich, is a flexible Internet platform for the automobile industry that connects OEMs and Tier-1s engaged in direct procurement to parts suppliers. The OEMs who use SupplyOn include BMW, Bosch, Continental, and Siemens VDO Automotive. SupplyOn has more than 9,000 parts suppliers and 25,000 registered users. The process of direct procurement, as opposed to catalog procurement, is one in which the OEMs solicit bids from suppliers to make specific types of parts. In each deal, the design for the part must be communicated clearly to the supplier, a deal is struck, manufacturing begins, and parts are delivered. The supply chain in the automobile industry uses a variety of different models for relationships between suppliers and OEMs, such as KANBAN, Delivery Control Monitor, and Vendor Managed Inventory (VMI). All of the communication between the OEM and the parts supplier, from the collaboration on the design to the flow of information needed to manage the scheduling and manufacturing of parts, takes place through SupplyOn. The advantages to both OEMs and parts suppliers are enormous. OEMs are able to pay one integration cost, that of adapting their systems to use SupplyOn, which then creates thousands of relationships which can be used repeatedly. Both OEMs and parts suppliers participate in customer councils that establish strategic requirements and expert groups that define the detailed processes. SupplyOn then implements these designs. Figure 3-7 shows SupplyOn's architecture. Each SupplyOn solution supports, standardizes, and automates a different aspect of the OEM-supplier relationship. The collaboration rooms and the business directory are used as relationships are being set up. The sourcing manager provides a framework for the request and offer process, the document manager for document exchange. Web EDI and inventory collaboration direct the flow of information during automated supply chain processes such as VMI. Problem resolution and performance monitoring of suppliers are also provided. Figure 3-7. SupplyOn's architecture The way that SupplyOn has replaced thousands of direct, company-to-company connections with a standardized set of relationships automated through a central hub, the way that this implementation process is managed, and the way that services will be introduced to enhance the flexibility of the platform contain several lessons for companies on the path to ESA. First, the way that SupplyOn changes the relationships, shown in Figure 3-8, is a perfect illustration of the benefits of loose coupling. Thousands of ad hoc, point-to-point connections are replaced by a much smaller number of standardized relationships that fit into a system of best practices designed by participants. This sort of simplicity through design, heavily informed by users with their process needs in mind, mimics the design process for enterprise services and composite applications. One key element of SupplyOn is a model of all of the business relationships that is stored in a master data repository. This model keeps track of who is delivering which parts, which supply chain processes have to be used, and exactly where they should be delivered, along with several other details. Second, the process of bringing OEMs and suppliers on board has been standardized. When a new OEM arrives at SupplyOn, the first order of business is to integrate the Figure 3-8. SupplyOn reducing complexity OEM's system with SupplyOn's. Then SupplyOn takes responsibility for reaching out to that OEM's supplier network, convincing them to join SupplyOn, signing contracts, and then performing any integration or training needed to allow the suppliers to use the solutions. To ease the change management required on all sides, SupplyOn offers services for rollout management, process implementation and training, customer support (24/7 in five languages), in addition to technical services for hosting, portal integration, connectivity, and security assurance. SupplyOn has, in essence, productized the change management process. While implementers in most companies may not have as clear a target as SupplyOn has, it is clear that similar problems will appear as ESA is applied to different applications and areas of a company, and that developing a standard approach and attempting to build skills and learn from experience is clearly the right approach. SupplyOn implements this approach through close collaboration with the purchasing officers at the OEMs, who work with SupplyOn to craft an adoption plan that takes into account the number of global locations, their readiness to migrate to a new process, the priority of each location, expected barriers to adoption, and so forth. As an organization, SupplyOn has a huge stake in getting change management right because it benefits from increased use of its solutions. This sort of incentive can be a powerful agent of change. Third, SupplyOn plans to expand its offerings through services at all levels. It also will offer each of its solutions as a suite of services so that an OEM or a supplier has the option of using the services to incorporate SupplyOn solutions into existing portals instead of using the SupplyOn UIs. SupplyOn will be able to use these services to create special-purpose products to meet the needs of various customer groups. On the back end, XML and EDI messages that are used to automate supply chain processes will be supplemented and, in some cases, replaced by enterprise services. SupplyOn has a focused mission to standardize and automate certain relationships that its users fund. IT departments are essentially in the same position with respect to their companies and could benefit from imitating at a company level some of the architectural and change management ideas that SupplyOn has so successfully implemented. |

EAN: 2147483647

Pages: 265