Section 8.3. ESA in action: Elsag

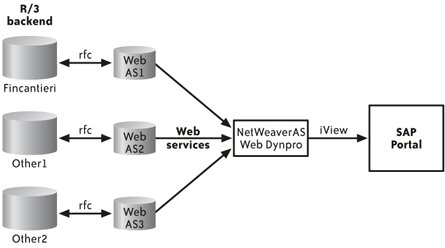

8.3. ESA in action: ElsagElsag's story shares much in common with the example we used earlier for service discovery. Like the real world, Elsag's situation was even more complex. Elsag is the strategic IT solutions arm of the Finmeccanica Group, an Italian aerospace, defense, and transport giant composed of more than 100 subsidiaries and 51,000 employees located across Europe. Elsag applies its IT expertise on behalf of customers operating in each of those areasincluding its corporate siblingsand in the telecommunications, utilities, and banking industries. The company has embraced enterprise services as a means to integrate disparate sources of data and improve process efficiency at both its customers and its siblings. One of Elsag's largest customers is Fincantieri S.p.A., a shipbuilding firm that is a key supplier of the Italian navy. Fincantieri asked Elsag to create a solution for a maintenance and supply chain problem troubling its client. Each of its vessels is built using components from hundreds of contractorsFincantieri provides the hulls, and others supply armaments, communications systems, etc.involving considerable overlap and integration. But due to security and competitive reasons, there is little to no communication between the inventory systems of each supplier. So when the navy needed to make maintenance requests, the challenge usually became "from whom?" Navy technicians needed to know exactly which combination of suppliers were responsible for which parts of the systems in question or else considerable time and energy would have to be spent in the error-prone process of asking likely suspects whether a needed part was theirs and starting over when, more likely than not, it wasn't. Fincantieri asked Elsag to implement a two-step solution that could combine the figuration scheme of each shipthe tree describing the components' relationships to each otherwith each component's supplier in a single window. The first step would create a consolidated bill of materials covering every component aboard each ship by linking the backend systems of each supplier and integrating them into a single window. The second step would allow navy engineers to send a maintenance request to any supplier using an interactive form available from that window. Elsag engineers used SAP NetWeaver to create a web application that could communicate with each supplier's SAP R/3 implementation via enterprise services. Using SAP NetWeaver, Elsag created enterprise services to provide access to remote function calls that query the inventory tables within the production modules of each supplier's variation on R/3 (see Figure 8-22). The web application then collected the data and presented it using an iView in a single portal interface. Figure 8-22. Elsag ship maintenance solution This first step has already successfully been implemented, saving countless hours of what was previously a trial-and-error process. With a complete bill of materials available at a glance, navy technicians are able to quickly identify needed parts and contact the respective suppliers. Elsag hopes to streamline this process further in the project's second phase, in which a single form in the portal interface will automatically pass maintenance requests to the appropriate supplier without prompting from the user. To do this, Elsag will write new enterprise services, passing the request along to the appropriate R/3 module. All of the underlying functionality will be invisible to the user. Elsag also used web services to centralize the treasury of its corporate parent, the Finmeccanica Group. Prior to Elsag's solution, each of the Group's 100+ subsidiaries maintained its own accounts for the conduct of operations. While flexible, this financial structure also required each unit to keep cash on hand that could be better put to work elsewhere in the Group and made it difficult to negotiate favorable lending terms with the Group's banks and to monitor the performance and spending behavior of each subsidiary. Because the Group's banks communicated directly with the Group's management, and because each subsidiary continually needed to request additional funds, the Group decided that a centralized corporate treasury would be the more effective solution. In order to centralize the treasury in principle without having to drastically change business processes or rewrite millions of lines of code, Elsag was asked to create a solution that could distribute funds to the Group's subsidiaries from the treasury on a just-in-time basis. In practice, this meant using enterprise services to connect the Group's SAP R/3 systemwhich consolidates the holding company's accounts with data arriving from the Group's bankswith each subsidiary's own financial planning unit, as shown in Figure 8-23. Elsag used SAP NetWeaver to create a portal application, which managers at each company use to request funds from the central treasury. This way, the Group is able to leverage a single R/3 implementation across all of its subsidiaries while at the same time maintaining centralized control over its finances. Figure 8-23. Elsag's centralized financials |

EAN: 2147483647

Pages: 265