Schneider National

Schneider National[4]

Schneider National Inc. today is the largest "truck load" transportation company in the U.S. In the late 1990s, Schneider's annual revenues were approximately $3 billion, and it had 20,000 employees.

Schneider's Beginnings

Schneider began in 1935 when A. J. "Al" Schneider sold the family car to buy his first truck. The company grew steadily and began acquiring other trucking companies to increase the depth and range of its operations. Don Schneider, Al's son, became CEO in 1973 and restructured Schneider into a holding company with diverse trucking-related units.

Deregulation and Lean Manufacturing Bring Change

The Motor Carrier Act of 1980 deregulated the U.S. trucking industry, bringing new opportunities and threats for industry participants. Trucking companies gained much greater leeway in what services they could provide, how they could price them and where they could operate. This led to a tripling of the number of trucking companies. But brutal competition saw 12,000 of these companies go bankrupt.

In the 1980s and 1990s, manufacturers adopted just-in-time (JIT) manufacturing techniques, which had unexpected effects on the trucking industry. Trucking firms now had to provide fast, reliable deliveries of smaller loads. With JIT, a botched pickup or a late-running truck had worse consequences for the receiving company.

Thus, manufacturers started rating trucking companies on their quality of service, especially on-time delivery. Yet tighter delivery schedules of smaller loads meant less revenue per trip and more "deadhead trips" (trips with an empty truck). Because the costs to operate a lightly-loaded (or empty) truck are almost as high as those of operating a full one, carriers saw increased costs per item delivered. In the early years of JIT manufacturing, customers grudgingly paid the costs of deadhead return trips and less-than-full truckload service, but they were constantly pressuring trucking companies to trim such costs.

Thus, deregulation and new manufacturing methods created new demands on trucking companies both to reduce their costs and improve their service. Schneider National chose to pursue a technological route to creating competitive advantage. Don Schneider was already using the power of IT to improve back-office chores such as billing and payroll. Then, a personal visit from Irwin Jacobs, president of QualComm, alerted Schneider to technology that would change the way his firm dealt with customers, drivers and trucks. Don Schneider saw that every part of the company might have to change if the technology was to truly be effective. In coming years, he oversaw the installation of sophisticated new IT systems, which became the basis for a new way of competing.

Schneider's IT Architecture

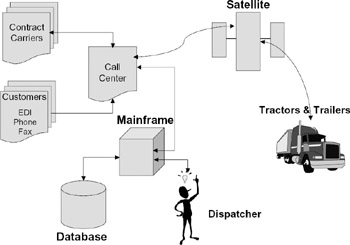

There are three major elements of Schneider's portfolio of technology to support the architecture depicted in figure 7.2.

Figure 7.2: Schneider National's Technology Architecture

SUMIT (Schneider Utility Managing Integrated Transportation) is a common realtime system for customers, carriers and Schneider management. It features: automation for orders (entry, management, and billing); load management to consolidate less-than-truckload (LTL) shipments; mode optimization to select the optimal carrier (surface, rail, water or air); real-time status and alerts.

EDI (Electronic Data Interchange) provides paperless linkages to many of Schneider's customers and handles more than 70 percent of the firm's invoices.

Satellite Communications Technology links Schneider's central control system in Green Bay, Wisc., to all the company's trucks throughout North America and, now, Europe. Costing $3,500 per truck and about .05 cents per mile, this system provides driver-to-control-center communication and location data to within 30 yards. This permits precise scheduling of departures, pick-ups and deliveries. The system greatly reduces drivers' non-productive time and increases asset utilization.

Schneider was the first in the trucking industry to invest in QualComm's OmniTRACS satellite system, starting in 1988. Schneider is now installing the technology on trailers as well as tractors and is again the industry pioneer. The system will let Schneider better manage its trailer assets by linking critical trailer location and status directly into the company's fleet management and logistics systems.

Although Schneider has chose to invest heavily in technology, the investments represented a means to an end, as Don Schneider's comment reveals:

When we first put a satellite in, I was telling one of our major customers, an automotive company, how good this communication would be. They said "Look Schneider, I don't care if you use carrier pigeons to talk to your drivers. All I care about is that your price does not go up and that you deliver on time, any way that you know how".

Impact of Technology at Schneider

A technology-intensive strategy both reduced costs and improved service levels. Costs dropped from $1 per mile in 1980 to $0.60 per mile in 1998, which more than paid for Schneider's hefty investments in IT. The fraction of late deliveries dropped by more than a factor of ten, even as delivery deadlines have tightened. Automated information systems reduced errors and improved responsiveness to customers. Decision support helped Schneider price its services and only accept profitable shipments. As a result, Schneider National has been called "an information system masquerading as a trucking line".

Although technology enabled efficient, high-quality operations, it did not, by itself, make Schneider successful. Concomitant changes in people's jobs and associated business processes were needed.

Changes for the Drivers Drivers are crucial to Schneider because they are the face of Schneider at customers' loading docks and because drivers account for some 40 percent of shipping cost. However, driver loyalty is low in the industry, as few drivers stay with any company, or with the profession, for very long.

When Schneider introduced the satellite communications system, the company worried that drivers would leave because of the "big brother" tracking features and complex equipment. But the drivers quickly learned and liked the system, a fact that illustrates the difficulty of predicting the effects of technology. Drivers liked the system because it boosted their productivity, mainly by reducing tedious paperwork and eliminating time wasted pulling off of the road to find a phone, call Schneider, get put on hold, etc. Because drivers are paid for miles driven, they especially value the opportunity to stay on the road.

Beyond the productivity improvements, Schneider's technology helped improve working conditions. Technology helps minimize the problem of drivers' time away from families. For example, drivers' families can send emergency messages at any time, which reduces drivers' fears of being unreachable while on the road. Technology also tracks the dates of birthdays and anniversaries to help drivers get their driving done and keep commitments to family.

Changes for the Customer Service Representatives Schneider's new technologies had a major impact on the customer service representatives (CSRs) that handle most of Schneider's day-to-day interactions with customers. Before digitalization initiatives like EDI, SUMIT, and satellite communications, customer service was a thankless job that involved handling routine requests and making frustrating attempts to contact drivers.

With satellite communications, CSRs can now pinpoint the location and status of shipments. Customers' changes to schedules can be confirmed quickly and confidently. But more importantly, technology reduced the number of routine calls because customers can check order status themselves via the Web. CSRs now have more interesting jobs tackling high-value customer needs, and they have the technological tools to meet these needs.

Changes for the Service Team Leaders Schneider's service team leaders provide management and support functions to drivers such as helping drivers get the load they need, making sure they get home on time, and tracking driver performance. Before digitalization, the job of a Schneider service team leader was a paperintensive process of managing driver logs, internal documentation on who carried which load, exception reports regarding problems, and a range of internal performance reports.

In creating a paperless system, Schneider largely automated time-consuming reporting functions. Now, team leaders handle 40 drivers each, up from 25 each. With less time spent on routine paperwork, service team leaders can now talk to each driver daily. Daily communication is vital to Schneider, because driver hiring and retention is a major constraint on growth. Ensuring that drivers get the miles they need to earn a living—and make it home on days they want to be with their families—improves driver loyalty and retention.

Changes for the Transportation Planners (Dispatchers) Transportation planners coordinate the movement of drivers, trucks, and loads. They try to minimize driving distance, minimize driver waiting times and equalize the availability of equipment nationwide, all within the constraints of scheduling demands and drivers' days off. Planners also face the vagaries of weather, road construction, and capricious customers.

In the past, planners did not know drivers' availability for the next load because they had to wait for the driver to call in. The frustrated planners typically generated long lists of tentative assignments and gambled on whether drivers would call for an assignment within the allotted window of time.

With satellite communications, transportation planners have more reliable estimates of truck locations and driver availability, and can send dispatch instructions and receive driver confirmation in minutes. Planners now coordinate activities more tightly to reduce waiting time for drivers, shorten deadhead trips, and prevent service problems.

Decision support software also changed the nature of transportation planners' jobs. In the past, Schneider relied on the experience and judgment of planners for all decisions. Since then, Schneider has embedded much of the analysis and decision-making process into software that can automatically balance the panoply of probabilities and contingencies required to assign drivers to loads. But the software supports—rather than replaces—transportation planners. Experienced planners can override the software's match-up of drivers and loads to cover complex exceptions related to the special needs of customers, drivers and the situation. Overall, planners override the system in only 20 percent of cases.

The preceding subsections illustrate how the work of all Schneider employees has changed. These changes have required everyone in the company to develop new skills and take on new responsibilities.

[4]The material on Schneider is drawn from a series of cases prepared by Andrea Meyer and Michael S. Scott Morton with the generous help of Schneider employees in 2000 and 2001.

EAN: 2147483647

Pages: 214