Appendix F Implementation in Large Plants

Implementing kanban in a large plant can seem like a daunting task. On the surface, it would seem to be extremely difficult to maintain all of the visual signals that would be required to control production in a large plant. In reality, this is not the case. A large plant will be run by a series of small kanbans, all of which are simple to operate . In fact, implementation is the most difficult task in operating a large plant with kanbans, since there are so many different kanbans that need to be installed and so many employees to train. Once the kanbans are implemented, it is simply a matter of auditing the kanbans, keeping people trained, and continuously improving the kanbans.

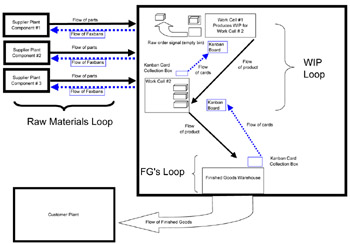

Figure F-1 demonstrates how these independent kanban loops are linked to control product flow through the entire plant. There are three basic kinds of loops : Finished Goods, WIP, and Raw Materials.

Figure F-1

Finished Goods Loops

The finished goods loops control the amount of finished goods (product ready to be shipped to the customer) that you carry. This loop is extremely important, as it protects your customer from disruptions within your process. Having finished goods inventory also allows you to respond quickly to unexpected increases in customer demand. And although disruptions within your plant can cost you money (high scrap or productivity losses), disruptions in shipments to your customer can cost you sales.

WIP Loops

The WIP loops control the plant's WIP inventory. As you continuously improve the kanban by reducing scrap, changeover times, and downtime issues, the size of inventories in this loop should decrease dramatically. While finished goods inventories protect the customer (and thus your sales), WIP loops only protect you from internal failures. Thus, they are a form of waste that needs to be eliminated.

Raw Materials Loops

The raw material loops control the flow of raw materials into your plant. Similar to WIP loops, these loops do not directly protect your customer. These loops, which protect you from downtime due to stock outs, are unique within your plant because they incorporate significant shipping times, supplier-imposed lead times, and freight considerations. The less-than -truckload shipments are costly and therefore can force you to carry significant raw inventories to minimize transportation. The milk runs (discussed in Chapter 9) or consigned inventory can be useful in dealing with these issues.

We can also use Figure F-1 to demonstrate how the different kanban loops in a large plant work together to control production. Let's assume we start in a stable plant with established kanban loops. The production process begins with a customer order.

- Based on the customer order, product is shipped from the warehouse, the kanban cards are removed from the product and placed in the kanban card collection box.

- The kanban cards are then collected by a material handler and returned to the kanban board in Work Cell 2. The returning cards authorize the work cell to begin production.

- When Work Cell 2 begins producing, it consumes WIP inventory produced by Work Cell 1. As the inventory is consumed, the kanban cards (from Work Cell 1) on the WIP containers are placed in the kanban card collection box. A material handler collects the cards and returns them to the kanban board in Work Cell 1.

- This authorizes Work Cell 1 to begin production to replace the inventory. This uses up raw materials. As the raw material bins are emptied, the empty bins are returned to the warehouse, authorizing the warehouse to order more materials. The warehouse generates faxbans, which are transmitted to the vendors .

- The vendor receives the faxbans, which authorize them to ship product. Once they ship product, they authorize their work cells to begin production, and the entire loop is repeated.

Thus, even though the plant is large and complex, all of the processes were driven by a customer order whose requirements rippled through the entire plant. Note that the order worked its way through the plant rapidly , and that the amount produced and ordered was linked closely to the amount shipped. Each individual work cell reacted to simple pull signals, yet they were actually part of a large, complex process. That is the power of kanban.

Preface

- Introduction to Kanban

- Forming Your Kanban Team

- Conduct Data Collection

- Size the Kanban

- Developing a Kanban Design

- Training

- Initial Startup and Common Pitfalls

- Auditing the Kanban

- Improving the Kanban

- Conclusion

- Appendix A MRP vs. Kanban

- Appendix B Kanban Supermarkets

- Appendix C Two-Bin Kanban Systems

- Appendix D Organizational Changes Required for Kanban

- Appendix E EOQ vs. Kanban

- Appendix F Implementation in Large Plants

- Appendix G Intra-Cell Kanban

- Appendix H Case Study 1: Motor Plant Casting Kanban

- Appendix I Case Study 2: Rubber Extrusion Plant

- Appendix J Abbreviations and Acronyms

EAN: 2147483647

Pages: 142