Environmental Analysis

Performance does not occur in a vacuum . Performance technology "recognizes individual and organizational realities when solving on-the-job performance problems." [27] Part of the organizational reality is the environmental support provided by the organization, the work environment, the work, and the worker. Environmental support has the potential to sustain actual performance or raise actual performance to the desired or optimal level.

Definition and Scope

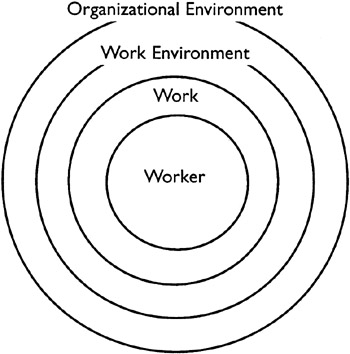

Environmental analysis is a process used to identify and prioritize the realities that support actual performance. The performance analysis section of the original HPT Model focused on the environmental support from the work, organizational, and competitive environments. Further efforts from the field (see Figure 3-3) made it possible to expand the work component of the HPT Model to include the work environment, the work, and the worker. [28]

Figure 3-3: ROTHWELL'S ENVIRONMENTS OF HUMAN PERFORMANCE

Purpose and Timing

The purpose of environmental analysis is not to identify problems, but to assess what is actually happening, both outside and inside the organization, that might help to explain why people do what they do. [29] The enhanced HPT Model (see Table 3-6) helps to focus the environmental analysis as follows :

-

Organizational environment analysis focuses on how the organization's external stakeholders (customers, suppliers, distributors , stockholders , regulators, etc.) and competition (the industry area within which the organization functions, for example, manufacturing, health care, education, retail, etc.) influence performance.

-

Work environment analysis focuses on what is happening inside the organization to support performance (resource allocation, tools, policies for recruiting and hiring, feedback, and consequences of performance or nonperformance).

-

Work analysis focuses on what is happening at the job design level (processes).

-

Worker analysis focuses on what is happening with the workers (knowledge, skills, capacity, motivation, and expectations).

| Organizational Environment (external performance support)

|

| Work Environment (internal performance support)

|

| Work (job design and performance support)

|

| Worker (individual performance support)

|

Environmental analysis may take place before, during, or after performance gap analysis. Often it is an integral part of analyzing actual performance. For example, while observing a performer on the job, the PT practitioner may note that safety procedures are clearly posted on the job site (work environment level) or that the worker does not have the necessary skill or knowledge to perform the job (worker level).

Analyzing the Organizational Environment

During an organizational environmental analysis the PT practitioner determines who are the external stakeholders and which of these stakeholders are most critical to the success of the organization. The organization's external stakeholders may include customers, suppliers, distributors, stockholders, industry regulators, etc.

Then the PT practitioner may review existing documents, such as customer surveys, and use interviews, group processes, or surveys to discover "how well the organization is interacting with its external environment." [30] One strategy is to collect information from within and outside of the organization and compare the findings. For example, one manufacturer randomly monitored conversations between product service representatives and customers on a product hot line, then surveyed both the product service representatives and the customers to identify facts and perceptions about what was happening at both ends of the hot line.

Analysis of the constantly changing competitive challenges facing the organization should also be part of the organizational environment analysis. This analysis should include an ongoing review of documents that chronicle industry activity, input from customers and knowledgeable employees , or product comparisons. Interviewing or surveying customers, sales staff, and even competitors may provide important insights into the competitive environment.

Analyzing the Work Environment

Work environment analysis looks within the organization to discover what is happening at the organizational level (big picture) and what is happening at the department, work team, or job level. The people who can provide the answers will include representatives from all levels of management, supervision, and the workforce. Seeking input "from groups likely to have unique perspectives, such as temporary workers, recently retired workers, or others who have intimate and recent firsthand knowledge of the organization" broadens the perspective of the analysis. [31] The information that is gathered during this phase of analysis should answer the following questions:

-

What factors or practices within the organization have influenced how effectively and efficiently people perform their work?

-

What factors or practices within the organization are most critical to achieving desired performance?

Open-ended questions are the best source of information, so surveys, interviews, or group processes are the analysis tools of choice.

Analyzing Work

Each job should be structured to enable the performers to achieve the desired goals. Work analysis concentrates on the job design and examines whether or not the job is structured to make it possible for the performer to achieve optimal performance. Effective and efficient job design includes the following:

-

Allocation of responsibilities among jobs to support rather than hamper the achievement of desired results

-

Logical sequence of job activities or work flow

-

Job policies and procedures that are clearly defined, documented, and accessible to the worker

-

Ergonomic design of the physical work space to minimize barriers to optimal performance. [32]

The PT practitioner may use interviews, surveys, or group processes to collect information from supervisors and workers. Observation and review of documents such as quality reports, cycle time studies, safety reports , etc. may also provide useful information.

Analyzing the Worker

At this level of analysis the PT practitioner looks at the performer to identify the performer's actual skills, knowledge, capacity, motivation, and expectations. To discover facts, opinions , or feelings, the PT practitioner may review personnel documents, observe performers, and use interviews, surveys, or group processes. In the following case study, the PT practitioner focuses on observing and interviewing the workers.

| |

The Internet is full of urban legends, stories that have circulated for years about alleged incidents that have occurred in one city or another. The following case study is based on a training legend that surfaces from time to time during conference sessions and in classroom discussions. Although there are several versions of this legend, the basic situation and the results of the analysis are the same for all of them.

Situation

A plant manager called the training department manager of a glass manufacturing company and said:" We need a training program for our product inspectors RIGHT NOW! When can you schedule a class?" The training department manager made an appointment for one of his performance consultants to visit with the plant manager.

Environmental Analysis

When the performance consultant arrived in the plant manager's office, the manager immediately prefaced his remarks by saying: "I know what I need, and I need it now. This problem is critical." He then proceeded to tick off the following points on his fingers:

-

Customers are complaining to the sales representatives that the glassware shipped to their retail shops contain imperfections.

-

The inspectors do not know how to inspect the glassware properly.

-

The inspectors need to be trained NOW before more orders are lost.

The performance consultant was prepared to make a case for identifying the performance gap and analyzing the cause before selecting an intervention. Fortunately she remembered the information she had just acquired from a publisher's online website, [33] so the consultant responded, "I know this is a critical problem and time is very important. I want to make sure that we do the best we can during the little time that we have and that we don't make false starts. We want to customize the solution to meet your needs and the needs of your employees and customers. I'm going to move very fast on this, using information we already have in our organization. Let's begin by talking about what it is you think is happening. I want to understand how you see it."

The performance consultant then asked the following questions:

-

Why do you want to move forward with this now?

-

What indicators moved you to take action?

-

If we are successful with this, what changes would appear?

-

How do you think the inspectors and their supervisors feel about this situation?

-

Are the inspectors and their supervisors ready to move forward on this?

The plant manager didn't know how to answer the last two questions, so he agreed to let the performance consultant observe the inspection process and talk to some of the inspectors and supervisors. He also agreed to let the performance consultant review the error data, read the customer complaint reports submitted by the sales representatives, talk to a sales representative and her dissatisfied customer, and visit the glass inspection work area.

Results

The performance consultant reviewed the documentation and talked to the sales representative and customer. She determined that over the past six months there was a 20 percent increase in the return of shipments due to imperfections in the glassware. She also determined that three customers had canceled large orders based on the continued shipment of imperfect products, and five more customers were threatening to do the same. They all cited that the only reason they had not canceled sooner was because the glass company had an established reputation for quality products and service to the customer.

When she visited the inspection area, the performance consultant was greeted with frustration and anger. The inspectors quickly pointed out that the lighting in the area was so bad that they were unable to see the glassware clearly in order to inspect it correctly. The shift supervisor showed her a stack of orders to the maintenance department requesting new lighting in the inspection area. Maintenance had replied that all their electrical engineers were tied up with construction of the new plant and that they would follow up on the request as soon as possible. The lighting problems had begun approximately six months before the visit from the performance consultant.

After listening to the inspectors and their supervisor and observing the inspection process, the performance consultant made an appointment with the maintenance department supervisor. The supervisor was aware of the requests from the inspection supervisors, but he had been informed that the new plant construction took precedence over department needs unless department needs were "significantly affecting life, limb, or production schedules."

The performance consultant prepared a report for the plant manager in which she listed the results of the environmental and the performance analyses. She recommended the following steps:

-

Authorize maintenance to develop an interim solution to the lighting problem (in this case, replacing some fuses and burned-out light bulbs ) and monitor the lighting in the area until a lighting engineer was available to analyze the problem and develop a long- term solution.

-

Monitor the quality inspection output for one month to determine if the quality improved with the lighting or the inspectors really needed additional training.

-

Provide an incentive for customers to remain with the company during the transition period.

-

Communicate biweekly with the inspectors, their supervisors, the sales representatives, and selected customers over the next six months to evaluate the effect of the intervention package.

Lessons Learned

-

Performance does not occur in a vacuum. Customer expectations, worker expectations, work environment, and organizational resource allocation all have an impact on actual performance.

-

Environmental analysis and performance gap analysis go hand-in-hand when identifying performance gaps.

-

Training is not always the intervention of choice.

This case study was written by Joan Conway Dessinger, Ed.D., The Lake Group. Used with permission.

| |

| |

| At this level of analysis... | Some of the issues are... |

|---|---|

| 1. Organizational Environment Level What is happening when the organization interacts with its external stakeholders and competition?

|

|

| 2. Work Environment Level What is happening inside the organization to support optimal performance?

|

|

| 3. Work Level What is happening on the job?

|

|

| 4. Worker Level What is happening with the workers?

|

|

| Based on Longdon (1995), Rothwell (I 996b), Rummler and Broche (1995), and Grant and Moseley (1999). | |

ISPI 2000 Permission granted for unlimited duplication for noncommercial use.

| |

[27] Seels and Richey 1994, p. 89

[28] Rothwell, 1996b, p. 33

[29] Rothwell, 1996b, p. 100

[30] Rothwell, 1996b, p. 100

[31] Rothwell, 1996b, p. 102

[32] Rummler and Brache, 1995, pp. 68 “69

[33] Rossett, 1999

EAN: 2147483647

Pages: 98

- Challenging the Unpredictable: Changeable Order Management Systems

- The Effects of an Enterprise Resource Planning System (ERP) Implementation on Job Characteristics – A Study using the Hackman and Oldham Job Characteristics Model

- Context Management of ERP Processes in Virtual Communities

- Data Mining for Business Process Reengineering

- Healthcare Information: From Administrative to Practice Databases