Tool 72: Facility Layout Diagram

| AKA | N/A |

| Classification | Changing/Implementing (CI) |

Tool description

A facility layout diagram displays floor layouts, manufacturing or service process flows, employee movement, possible bottlenecks, excessive cycle time, and other possible inefficiencies in the present layout. This tool prepares a layout of equipment, work areas, and storage areas useful in work flow analysis (WFA) and improvement efforts.

Typical application

-

To create a floor plan of the facility for tracing employee movement.

-

To identify possible co-location of activities and shorter distances of required movement.

-

To map process flows and loopbacks.

Problem-solving phase

| → | Select and define problem or opportunity |

| → | Identify and analyze causes or potential change |

| → | Develop and plan possible solutions or change |

| Implement and evaluate solution or change | |

| Measure and report solution or change results | |

| Recognize and reward team efforts |

Typically used by

| Research/statistics | |

| Creativity/innovation | |

| 2 | Engineering |

| Project management | |

| 3 | Manufacturing |

| Marketing/sales | |

| 4 | Administration/documentation |

| Servicing/support | |

| Customer/quality metrics | |

| 1 | Change management |

before

-

Process flowchart

-

Cycle time flowchart

-

Opportunity analysis

-

Mental imaging

-

Interview technique

after

-

Work flow analysis (WFA)

-

Activity analysis

-

Variance analysis

-

Potential Problem Analysis

-

What-if analysis

Notes and key points

For easy reference to any work area, use grid labeling of facility layout. Example:

Step-by-step procedure

-

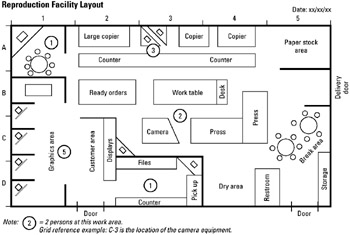

STEP 1 First, identify and observe the facility or work area for the normal work flow, equipment location, and the number of employees normally assigned to workstations. See example Reproduction Facility Layout.

-

STEP 2 Using drafting paper, prepare a facility layout diagram showing all major items or equipment, furniture, and other objects or areas of interest.

-

STEP 3 Name all drawn items, complete grid reference labeling, and identify the number of people working at certain locations.

-

STEP 4 Finally, check for accuracy and date the diagram.

Example of tool application

EAN: 2147483647

Pages: 326