Tool 60: Defect Map

| AKA | Defect Location Checksheet, Concentration Diagram |

| Classification | Data Collecting (DC) |

Tool description

A defect map displays the location of defects and simplifies the process of data collection and repair. Problem locations are marked so that repair staff know where to look.

Typical application

-

To point to the location of defects or problems on rejected products.

-

To mark or check off the locations of defects on an assembly diagram for the purpose of collecting frequency data of the various defects observed.

Problem-solving phase

| → | Select and define problem or opportunity |

| → | Identify and analyze causes or potential change |

| Develop and plan possible solutions or change | |

| Implement and evaluate solution or change | |

| Measure and report solution or change results | |

| Recognize and reward team efforts |

Typically used by

| Research/statistics | |

| Creativity/innovation | |

| 4 | Engineering |

| Project management | |

| 1 | Manufacturing |

| Marketing/sales | |

| 3 | Administration/documentation |

| Servicing/support | |

| 2 | Customer/quality metrics |

| Change management |

before

-

Data Collection Strategy

-

Checksheet

-

Checklist

-

Observation

-

Quality Chart

after

-

Pareto Chart

-

Problem Specification

-

Failure Mode Effect Analysis

-

Potential Problem Analysis (PPA)

-

Countermeasures Matrix

Notes and key points

-

Use checksheets to record and summarize various defect map data.

Step-by-step procedure

-

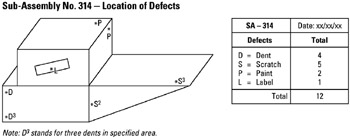

STEP 1 A defect map can be drawn for specific parts, assemblies, or complete units of product. Assembly drawings can also be used as defect maps. See example Sub-Assembly No. 314—Location of Defects.

-

STEP 2 During inspection of parts, assemblies, or units, the observed location of defects is marked on defect maps.

-

STEP 3 Defect types, locations, and frequencies are summarized on a checksheet as shown in the example.

-

STEP 4 Use this type of historical defect data to prepare a problem specification statement.

-

STEP 5 Provide notes on drawings, and date all documentation.

Example of tool application

Sub-Assembly No. 314—Location of Defects

EAN: 2147483647

Pages: 326

- ERP System Acquisition: A Process Model and Results From an Austrian Survey

- Context Management of ERP Processes in Virtual Communities

- Distributed Data Warehouse for Geo-spatial Services

- Data Mining for Business Process Reengineering

- Development of Interactive Web Sites to Enhance Police/Community Relations