8.6 ABB Automation Technology Products

|

| < Day Day Up > |

|

ABB is a leader in the field of power and automation technologies that enable utility and industrial customers to improve their performance while lowering environmental impact. The power technologies division serves industrial and commercial customers and electric, gas, and water utilities with a broad range of products, services, and applications for power transmission and distribution. The automation technology products division serves customers in the automotive, chemicals, manufacturing, marine, and many other industries. The technology is based on the industrial information technology concept, which integrates diverse automation and information technologies in real time.

ABB Automation Technology Products consists of a number of units that develop different products for industrial automation (e.g., industrial robots, automation control, operation, and information systems used in a wide range of industrial processes from very small control systems to large plant automation and information systems).

This case study contains a brief description of the PDM and SCM tools used in the ABB Automation Technology Products unit in Malmö, Sweden (referred to as ABB Malmö in the following). ABB Malmö has recently developed the ABB Common Controller used for data acquisition in different processes and for control of these processes. In addition to this new product, the unit has developed and maintains several families of similar products, such as Controller 800M, Controler 800C, I/O 800, and I/O S200.

8.6.1 Data management tools

ABB Malmö previously made use of a system designated construction base, which provides system developers with a degree of support during the production phase. This tool, now obsolete, stored information about the system-building process. It has now been superseded by several tools, both commercial and in-house tools, which together constitute an information, software, and product data management system. The most important of the tools used currently are:

-

Documentum. Documentum [3] is a commercial document management tool used as a central documentation and product structure archive. (For more about document management tools, see Chapter 11.) Documentum supports distributed management based on a client/server concept. All information about all relevant products, both software and hardware, is stored at a central server accessed via the Internet.

-

Capri. Capri is a program package developed by ABB, used as a plug-in for Documentum for simpler management of the product structure within the product information model implemented in Documentum. It includes a graphical user interface and procedures for automatic creation of certain documents. Capri is used by technical product and project managers.

-

ABB Library. This is a structure of a particular data in Documentum, an internally developed tool package that provides views of this structure. The data includes additional information about the products and components (e.g., different manuals and product guides).

-

SAP R/3. SAP R/3 [4] is a commercial ERP tool. ERP tools include much of the functionality present in PDM or other document management tools. SAP R/3, however, focuses on the commercial aspects of the entire PLC rather than on the development and production phases. ABB uses SAP R/3 for storage of product and manufacturing data, such as information about subcontractors, inventories, and prices. Information about a particular product is transferred from Documentum when the product is released.

-

Visual SourceSafe (VSS). VSS is a commercial SCM tool (see Chapter 10) used in the development and maintenance of software products. Documents related to the software development process, function specifications, test specifications, and implementation proposals are also saved in a VSS repository. Later, when the product is released, some of these documents can be exported to Documentum.

-

PVCS Tracker. PVCS Tracker is a commercial tool for error handling, change proposals, and issue management.

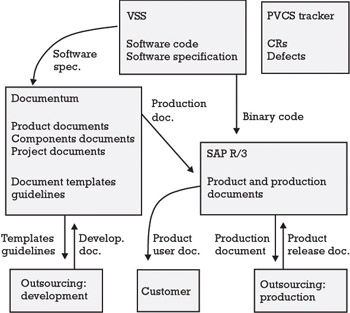

The relationships between the tools are shown in Figure 8.21. Today, most of the relevant information is transferred between tools more or less manually. The company is aware that a more automatic transfer would provide more effective support during development cycles, and the overall process would be shortened. Some new tools are being evaluated, and there are certain ongoing activities in which the possibility of a more efficient use of existing tools is under investigation.

Figure 8.21: Tools supporting product and document management.

8.6.2 Product structure

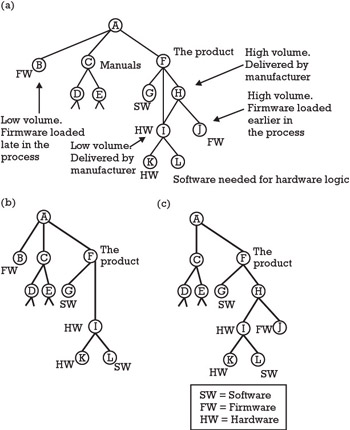

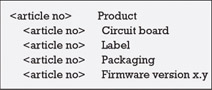

To manage products, ABB Malmö identifies a product structure that describes realized products. All aspects and parts of the entire product are included, including product documentation, wrapping, and the product itself, whether realized in hardware or software, outsourced or developed in-house. A product structure includes not only a particular product version, but may contain many optional nodes [see Figure 8.22(a)]. This may be because the volume of production determines when firmware is to be loaded—and by whom—or whether a specific functionality should be realized in hardware or software. Firmware is low-level software loaded on a circuit board (e.g., the software implementing the protocol on an input/output board). The same hardware can be loaded with different firmware, implementing different protocols. The volume of production of a product, which can vary between more than 10,000 per year and 100 per year, affects the optimal product structure. A central processing unit part for several system families may have a generic hardware. The production volume determines to a degree when the firmware is to be loaded into the central processing unit hardware. For a low volume, the firmware is loaded late, at the time of packaging or even by the customer [Figure 8.22(b)]. With a high volume, the firmware is loaded early, often by the manufacturer [Figure 8.22(c)]. This indicates the importance of a flexible product structure. When a product is to be manufactured, a tree of concrete nodes, referred to as a part list, is specified. It is important to define unambiguously the constituent parts of a product. Each node designated an article or part can be realized in different ways: developed in-house, outsourced, or bought as COTS. Irrespective of its origins, it always has an article number. Figure 8.23 depicts an example of an article and of what it consists (in this case four parts—articles). Each part can, in turn, be complex and can consist of articles itself.

Figure 8.22: Example of a product structure: (a) product structure, (b) product low volume, and (c) product high volume.

Figure 8.23: An example of an article and its constituent parts.

Each part has an article number of its own—down to a certain level. ABB has full traceability down to the manufacturer of a circuit board. (Only approved manufacturers are used by ABB and specified in the SAP/R3.) Some companies have traceability down to the batch number of the circuits used. The “same” hardware has the same part number, irrespective of manufacturer. Thus, it is impossible, in the product structure and in the BOM, to see who manufactured. For example, a resistor (several alternatives may be specified in the SAP/R3) on a CPU card.

8.6.3 Conclusion

Product data management at ABB Malmö is typical of that of many industrial enterprises. It is often a result of an organic and continuous improvement of process support. A complete support is built from several tools, often of different generations and based on different technologies. Interoperability and process efficiency is achieved by additional, often adhoc, building tools and import/export utilities and by specification of rules that permit a semiautomatic information flow. In an ideal case, a few wellintegrated tools would be used. However in reality, it is often impossible to achieve as such a migration to new tools, as it can be prohibitively expensive.

Product structures and how they are supported in PDM is explained in Chapter 2. The importance of tool integration and how this could be performed successfully is discussed in Chapter 6.

|

| < Day Day Up > |

|

EAN: 2147483647

Pages: 122