Chapter 2: General Description of PDM

|

| < Day Day Up > |

|

It is a capital mistake to theorize before one has data.

—Sir Arthur Conan Doyle

2.1 Introduction

Hardware design is not only about hardware. Modern design environments are highly computerized, containing a wide variety of tools producing vast amounts of information. This information produced in different formats, in widely dispersed locations, on heterogeneous computer networks, needs to be stored and related to other data. Furthermore, geographical dispersal of design teams has made the management of design data much more complex—a pile of plans in a single location is no longer an option. Gone are the days when the design of a product and related information could be found in a central location in drawing filing cabinets, using a manual process for storing, managing, and controlling documents.

PDM systems have been developed to manage the large volumes of information created in modern design environments more effectively and to meet demands for faster development of more complex products. These systems provide access to and control of information and support different kinds of processes (e.g., approval of documents and storage of documents in archives). Typically, PDM is used for work with files and database records. These include information such as product configurations, specifications, CAD drawings, images (in the form of scanned drawings), general documentation, and numerical control part programs. In short, all product information required throughout the life cycle of a product can be managed by PDM systems.

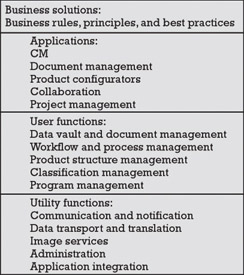

PDM functions can be classified in different levels, as shown in Figure 2.1. All basic functionality within PDM is divided into user functions and utility functions. A PDM application is a combination of one or more PDM basic functions. Examples of applications include CM and project management. It may be necessary to establish principles and practices for PDM applications to be able to use PDM efficiently. These principles, business rules, and best practices constitute the business solution for the company.

Figure 2.1: A PDM business solution model.

The description of PDM in this chapter is an overview for those working within the SCM area and for beginners. A survey of PDM is provided in [1], and more information can be obtained from the PDM Information Center [2]. For a more comprehensive description from a research perspective, we recommend [3, 4]. We give a list of most commonly used PDM tools in Chapter 10.

We begin this chapter with a survey of the history of PDM (Section 2.1.1). We provide a definition of PDM (Section 2.1.2) and describe all of its functions (Section 2.2). We then present the more technical details of PDM—the information architecture (Section 2.3) and the system architecture (Section 2.4). Some applications are discussed in Section 2.5, and we finally consider certain trends in the use of PDM (Section 2.6).

2.1.1 History overview

The management of product data is not a new activity. Traditionally, text documents and drawings have been archived on paper. These had to be identified and classified. Provided that the amounts of information produced were reasonable, the storage of documents in filing cabinets was manageable—even if the manual work associated with physical archives could be inconvenient. As computer technology evolved, more and more product data was created in digital form. This could be stored on file servers, thus creating a demand for systems for managing such files.

When PDM systems were introduced, the management of design documents was the most common task. For example, many companies began using PDM for more effective control of their CAD documents. PDM functions were developed both as separate systems and as data management modules in CAD systems.

Manufacturing is another area that has influenced PDM. Product structures were previously defined in text documents. When the use of databases developed in the 1970s, before the use of digital documents became wide spread, many companies began to store their product structures in databases. Companies developed their own database applications, and the design departments were responsible for feeding the databases with information. As design departments and production facilities were frequently located separately, and designers and manufacturing engineers had different demands on the content and breakdown of information, the design and manufacturing departments used separate databases. In the late 1980s, commercial PDM systems became available. The PDM systems used a product structure similar to the manufacturing structure to organize the documents. Product structure management became an issue for PDM. Initially, systems developed in-house were used to manage product structures, with the PDM systems being mainly used as advanced file systems to manage design documents. This is still the situation within some companies; legacy systems are hard to replace because they handle critical data and have many users and multiple connections to other systems.

2.1.2 PDM definition

One definition of PDM is:

PDM is the discipline of controlling the evolution of a product and providing other procedures and tools with the accurate product information at the right time in the right format during the entire PLC.

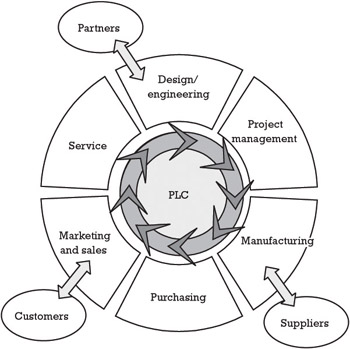

As depicted in Figure 2.2, this involves supporting processes, such as development, manufacturing, marketing, sales, purchasing, and extended enterprises (e.g., suppliers, subcontractors, customers, and partners). Even though much of the information in the PDM system is created in the design phase, other people with different roles (e.g., partners, suppliers, and customers) use and create information during other phases. Figure 2.2 shows how the different support activities are gathered around the product and its life cycle.

Figure 2.2: PDM supporting the whole PLC.

Other designations on this area are collaborative product definition management (cPDM), product information management (PIM), PLC management (PLM), and electronic product data management (ePDM). Even if there are differences in the definitions, the terms and the meaning are still the same.

Note the difference between the concepts PDM and PDM system. PDM is a generic name for a set of rules, principles, and methodologies that comprise functions from different systems. A PDM system is an implementation (i.e., a set of particular tools) for managing product information and the implemented processes. In this book, we use the term PDM to refer to a PDM system unless otherwise stated.

In the context of today’s PDM vision, a PDM system is more accurately described as an information infrastructure—an infrastructure that provides users with support in performing their tasks by means of the different functional models that it incorporates and by means of other integrated software systems. PDM is therefore both a base for different systems and an information management system into which other applications can be integrated. Some applications present in PDM will be discussed in Section 2.5 as separate applications.

|

| < Day Day Up > |

|

EAN: 2147483647

Pages: 122

- Cisco IPC Express System Components

- The Cisco 7905G and 7912G IP Phones

- Configuring and Monitoring Via Network Management Systems Using the Cisco CME AXL/SOAP Interface

- Managing Cisco IPC Express Systems by Managed Services and Enterprises

- A Cisco Unity System with a Network of Cisco CMEsCentralized Voice Mail Architecture