EXTERNAL PRODUCTION PLANNING AND CONTROL

|

|

EXTERNAL PRODUCTION PLANNING AND CONTROL

(Process Manager: Production Manager and Production Progress Manager)

The management of LSB production process is quite complex, because of the presence of both internal and external production units. As an example, the line "LSB elegant man" is managed internally, while all women's shoes are produced by third-party manufacturers. The situation is even more complicated for the sport line, because the processing of leather is outsourced while the assembly of sport shoes is managed by LSB production lines.

Moreover, the production planning and control process significantly affects the whole business performance, because its output is strictly related to the collection development and the commercial performance (in terms of order collection).

In particular, LSB must necessarily complete the collection development and define the price-list before the beginning of the first shoe fair in October. If this requirement is not satisfied (LSB often does not succeed in defining the complete price-list before the beginning of the fair), then customer orders will be confirmed only about one month later, after the communication of the exact price of each model. Obviously, this problem makes the planning and management of external production much more difficult to be performed.

In short, the correct carrying out of the coding process would allow a punctual definition of the price-list, a necessary condition to collect definitive orders. These, in their turn, would consent to correctly manage the external production planning. Today, instead, LSB often requires external partners to produce at excessive speed, because of the too short period between the order confirmation and the delivery terms.

Another main problem concerns the external production progress control. Both the strategic choice of performing built-to-order production and the choice of partially outsource production activities, demand an efficient and effective integration with external partners during the production process, in order to assure the respect of the delivery terms.

Regardless of production planning limitations, LSB finds it very difficult to get updated information about production activities from third-parties because of the total lack of information system integration. Thus, when a customer complains about a delay in delivery, the sales manager asks the production manager for an explanation. In such situations, the production manager should be able to provide real time information about the progress of outstanding orders. Instead, LSB production manager has to make many phone calls and send many faxes to achieve a clear view on the updated situation of the required order.

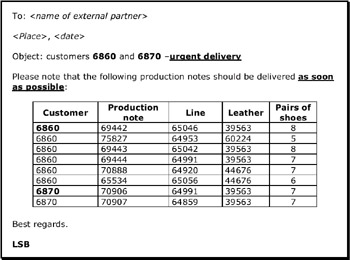

Figure 11 shows a fax that was sent to an external partner by two customers complaining about a delay in delivery.

Figure 11: A Fax Sent by LSB to an External Partner

This fax shows the very inefficient way of managing information, due to the lack of both technological and organizational integration. It is important to underline that the lack of technological integration not depends on LSB only because most of its external partners do not even make use of a personal computer. Actually, LSB tried to integrate its information system with one of its partners, which has a very similar software architecture (based on Open VMS operating system); but their way of managing information flows is questionable since data about the production progress are stored on a floppy disk which is every day manually transferred to LSB by an employee.

|

|

EAN: 2147483647

Pages: 367